Specialty Surfactants Beyond LABSA and SLES: Emerging Molecules for Cleaner Formulations

For decades, Linear Alkylbenzene Sulfonate (LABSA) and Sodium Laureth Sulfate (SLES) have dominated the surfactant landscape in cleaning and personal care formulations. These workhorses of the industry built their reputation on reliable performance, excellent foaming properties, and cost-effectiveness.

However, the tide is turning. Today's consumers demand products that clean effectively while being gentle on skin and kind to the environment. Regulatory bodies worldwide are tightening restrictions on ingredients with environmental persistence or toxicity concerns. This convergence of consumer awareness, ecological imperatives, and regulatory pressure is driving formulators to explore a new generation of specialty surfactants that promise cleaner, greener, and more sustainable cleaning solutions.

The Limitations Driving Change

While LABSA and SLES have served the industry well, their limitations have become increasingly apparent. Both surfactants are primarily petroleum-derived, contributing to carbon footprints and raising sustainability questions. LABSA, in particular, has faced scrutiny for its environmental persistence and potential aquatic toxicity. SLES, though milder than its predecessor Sodium Lauryl Sulfate (SLS), can still cause skin irritation in sensitive individuals, especially at higher concentrations.

Beyond environmental and dermatological concerns, these conventional surfactants face performance challenges in modern formulation requirements. As consumers seek concentrated products that work effectively in cold water to save energy, and as water hardness varies globally, formulators need surfactants that can deliver consistent performance across diverse conditions. The quest for biodegradable, renewable, and multifunctional ingredients has opened the door to innovative surfactant molecules that address these limitations head-on.

Alkyl Polyglucosides: The Natural Performers

Alkyl Polyglucosides (APGs) have emerged as one of the most successful alternatives to conventional surfactants. Derived from renewable plant materials - typically combining fatty alcohols from coconut or palm oil with glucose from corn or potatoes - APGs represent a bridge between natural origins and robust performance.

What makes APGs particularly attractive is their exceptional dermatological profile. They're among the mildest surfactants available, making them ideal for products targeting sensitive skin or baby care applications. Their excellent biodegradability means they break down rapidly in wastewater treatment and natural environments, leaving a minimal ecological footprint.

Performance-wise, APGs excel in hard water conditions and maintain cleaning efficacy across a wide temperature range, including cold water washing. They produce moderate, stable foam and work synergistically with other surfactants, allowing formulators to create optimized blends that balance cost and performance. Major brands in household and personal care have increasingly incorporated APGs into their premium "natural" and "eco-friendly" product lines, signaling strong market acceptance despite their higher price point compared to conventional options.

Methyl Ester Sulfonates: The Cold-Water Champions

Methyl Ester Sulfonates (MES) represent another significant advancement, particularly for laundry applications. Produced from natural fats and oils through esterification and sulfonation, MES surfactants deliver superior cold-water detergency compared to LABSA, addressing one of the key performance challenges in modern laundry formulations.

The environmental credentials of MES are compelling. They exhibit excellent biodegradability, rapidly breaking down into non-toxic metabolites. Their performance in hard water rivals or exceeds conventional sulfonates, while showing reduced aquatic toxicity. Palm oil-derived MES has gained particular traction in regions focused on sustainable palm oil sourcing, though soy and other vegetable oil sources are also being explored.

For powder and liquid detergent manufacturers, MES offers formulation flexibility and the ability to create concentrated products that meet stringent environmental standards while delivering the cleaning performance consumers expect. As energy-conscious consumers increasingly wash clothes in cold water, MES-based formulations are positioned to capture growing market share.

Biosurfactants: Nature's Sophisticated Solutions

Perhaps the most exciting frontier in surfactant technology lies in biosurfactants - molecules produced through microbial fermentation. Sophorolipids and rhamnolipids exemplify this category, offering not just excellent surfactant properties but additional functional benefits that conventional molecules cannot match.

Sophorolipids, produced by yeasts fermenting plant oils and sugars, possess remarkable surface-active properties alongside antimicrobial activity. They're completely biodegradable, non-toxic to aquatic life, and can be produced from waste streams, contributing to circular economy principles. Rhamnolipids, synthesized by bacteria, offer similar benefits with even stronger antimicrobial properties, making them valuable in cleaning formulations where hygiene is paramount.

The challenge with biosurfactants has been production scale and cost. Fermentation processes are more complex and expensive than traditional chemical synthesis. However, significant progress in bioprocess engineering and economies of scale are gradually bringing costs down. Early adopters in premium personal care and specialty cleaning applications are proving the commercial viability of these molecules, paving the way for broader adoption as production capacity expands.

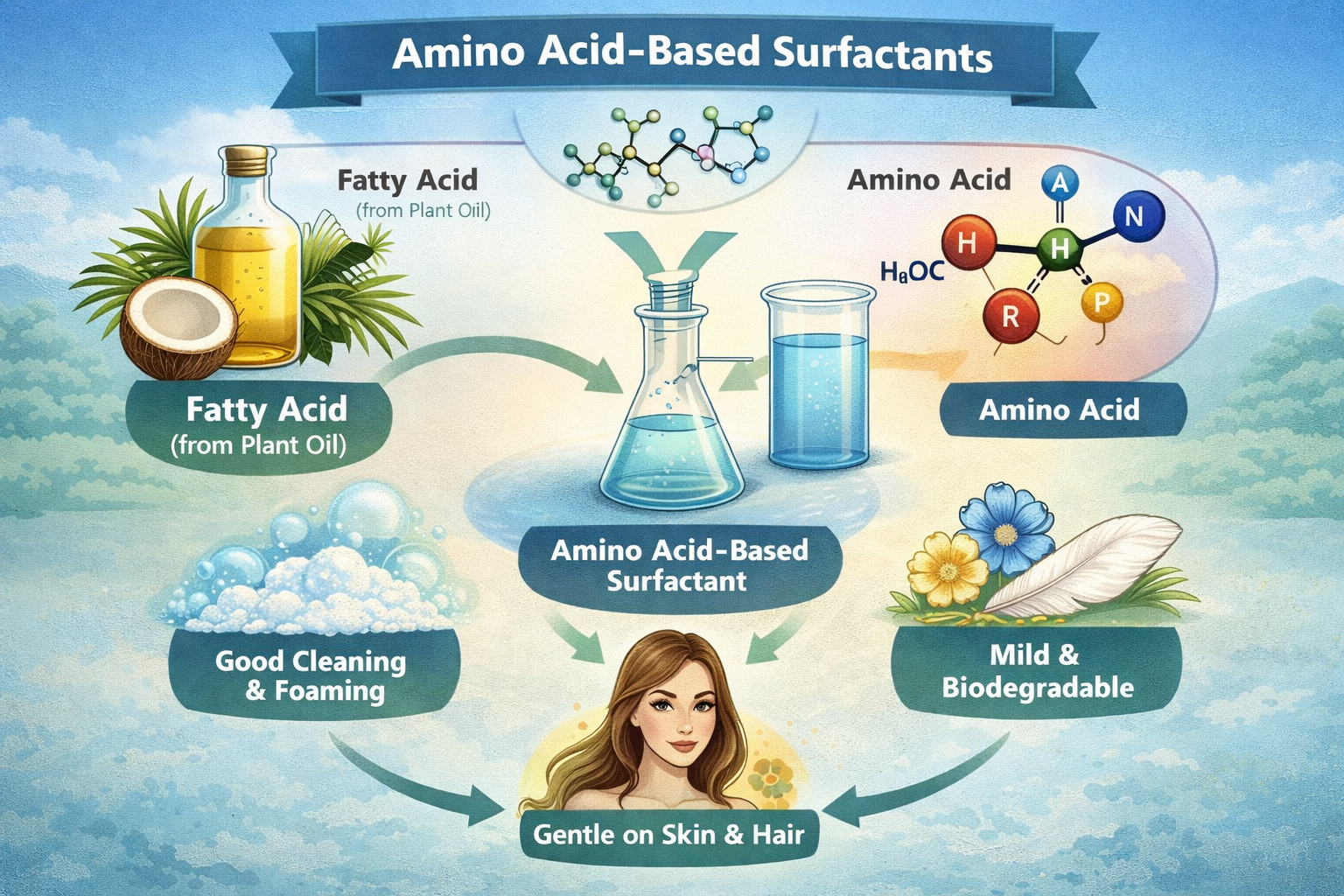

Amino Acid-Based Surfactants: Gentle Giants

Amino acid surfactants represent the premium end of the specialty surfactant spectrum. Derived from amino acids (the building blocks of proteins), these surfactants include acyl glutamates, sarcosinates, and isethionates. Their protein-related structure gives them exceptional skin compatibility, making them virtually non-irritating even to the most sensitive skin.

These surfactants are particularly popular in facial cleansers, baby products, and premium body washes where mildness is paramount. They produce fine, creamy foam and leave skin feeling conditioned rather than stripped. Their biodegradability and natural derivation align perfectly with clean beauty trends that dominate premium personal care markets.

The trade-off is cost; amino acid surfactants are significantly more expensive than conventional options. However, their marketing appeal and functional benefits justify premium positioning. Formulators often use them in combination with more cost-effective surfactants, leveraging their mildness to create balanced formulations that deliver both gentleness and value.

Sugar-Based Esters: Food-Grade Safety

Sucrose esters, sorbitan esters, and similar sugar-based surfactants bring food-grade safety profiles to cleaning formulations. Many of these molecules are actually approved for use in food products, which translates to exceptional safety for personal care and household applications.

These surfactants excel as emulsifiers and solubilizers, making them valuable in formulations requiring stable oil-water mixtures. Their natural origin and excellent biodegradability make them favorites in natural and organic certified products. While they may not match the raw cleaning power of synthetic surfactants, their gentle action and multifunctional properties make them valuable components in sophisticated formulations where multiple benefits are desired from single ingredients.

The Art of Formulation: Blending for Success

The reality of modern surfactant formulation is that it's rarely an either-or choice between conventional and specialty surfactants. Master formulators increasingly employ strategic blending, combining the cost-effectiveness of traditional surfactants with the performance enhancements and marketing appeal of specialty molecules.

A typical premium laundry detergent might use LABSA as the primary cleaning workhorse, supplemented with MES for cold-water performance and APG for enhanced mildness and natural positioning. This approach optimizes cost while delivering measurable performance improvements and sustainability credentials that resonate with consumers.

The key is understanding the synergies between different surfactant classes. APGs, for instance, boost the performance of anionic surfactants while reducing irritation potential. Amino acid surfactants can moderate the harshness of sulfates without sacrificing foam. These synergistic effects allow formulators to create products that outperform single-surfactant systems while managing costs effectively.

Regulatory Tailwinds and Market Forces

Regulatory developments are accelerating the shift toward specialty surfactants. The EU's stringent biodegradability requirements, microplastic restrictions, and ingredient disclosure mandates favor molecules with clear environmental profiles. Ecolabel certifications like the EU Ecolabel and Nordic Swan require specific biodegradability and toxicity thresholds that specialty surfactants often meet more easily than conventional options.

Consumer awareness is equally powerful. Transparency initiatives and ingredient scrutiny by advocacy groups have made surfactant selection a brand reputation issue. Products featuring recognizable, naturally derived surfactants command premium prices and shelf space, rewarding companies that invest in cleaner formulations.

Market analysts project robust growth for specialty surfactants, with biosurfactants expected to see double-digit compound annual growth rates through the next decade. As production scales up and costs decline, these premium ingredients will increasingly penetrate mainstream products, not just niche natural brands.

The Path Forward

The future of surfactant technology is dynamic and promising. Advances in synthetic biology and fermentation engineering are creating pathways to biosurfactants that were economically unfeasible just years ago. Computational chemistry and AI-assisted molecular design are enabling researchers to predict and optimize surfactant properties before synthesis, accelerating innovation cycles.

The industry is also exploring circular economy approaches, using waste streams as feedstocks for surfactant production. Agricultural residues, used cooking oils, and even captured CO2 are being investigated as sustainable raw materials. These innovations could further improve the environmental profile of cleaning products while enhancing supply chain resilience.

Conclusion

The surfactant landscape is undergoing its most significant transformation in decades. While LABSA and SLES will remain important for years to come, the emergence of APGs, MES, biosurfactants, amino acid derivatives, and other specialty molecules is fundamentally changing what's possible in cleaning formulations. These ingredients offer formulators unprecedented opportunities to create products that are simultaneously more effective, gentler, and more sustainable.

The transition requires investment, technical expertise, and a willingness to challenge established formulation paradigms. However, the benefits like environmental sustainability, regulatory compliance, consumer appeal, and product differentiation make this evolution both inevitable and desirable. Companies like DECACHEM, which specialize in innovative chemical solutions, are well-positioned to guide manufacturers through this transition, offering access to specialty surfactants and the technical support needed to reformulate successfully.

The cleaning products of tomorrow will be judged not just on how well they clean, but on how they clean, with minimal environmental impact, maximum safety, and renewable origins. Specialty surfactants are the key to meeting these elevated expectations, and the companies that embrace them today will lead the cleaner formulations of tomorrow.