The Future of Food-Grade Chemicals: Balancing Purity, Safety and Sustainability

Food-grade chemicals - substances approved for use in food processing, preservation, and formulation - play a vital role in ensuring that global food systems remain safe, stable and efficient. These include acids, stabilizers, minerals, preservatives, and countless functional ingredients that enable food manufacturers to meet quality standards and extend shelf life. But as the food industry transforms, the expectations placed on these chemicals are shifting more rapidly than ever before.

Today’s producers are navigating powerful pressures from three directions: increasingly informed consumers, tightening regulatory frameworks, and global environmental commitments. Consumers expect ingredient transparency, cleaner labels, and guaranteed safety from farm to fork. Regulators worldwide are demanding stricter compliance, traceability, and rigorous verification of purity and contaminant control. At the same time, environmental organizations and sustainability initiatives are urging manufacturers to reevaluate the full lifecycle of the chemicals they use - from raw material sourcing to energy consumption and waste management.

As a result, purity, safety, and sustainability have become equally important pillars shaping the future of food-grade chemicals. High chemical purity is no longer just a technical requirement - it is a foundation of trust. Safety standards must evolve alongside advances in science and production technologies. And sustainability is emerging as a non-negotiable priority as companies work to reduce their environmental footprint without compromising performance. Together, these forces mark a pivotal turning point for the food-grade chemical sector, pushing it toward cleaner, smarter, and more responsible innovation.

Understanding Food-Grade Chemicals: Types, Uses and Industry Challenges

Food-grade chemicals form the backbone of modern food manufacturing, ensuring that products remain safe, consistent, and appealing throughout their shelf life. These chemicals serve highly specific functions that cannot be replaced by standard raw materials alone, making them essential to both small and large-scale food processors.

Common Types of Food-Grade Chemicals

Preservatives help extend shelf life and prevent microbial growth, protecting foods against spoilage and potential health risks. Stabilizers maintain texture and consistency, ensuring that emulsions, gels, and suspensions remain uniform. Colorants enhance visual appeal and help manufacturers deliver a consistent product experience, while flavor enhancers boost taste and aroma without altering nutritional value. Additionally, processing aids - such as acids, anti-foaming agents, or pH adjusters - support efficient manufacturing by improving yield, refining texture, or enabling precise reactions during production.

Existing Challenges in the Industry

Despite their importance, the food-grade chemical sector faces several ongoing hurdles. Contamination risks remain a critical concern, especially in products requiring ultra-high purity, where even trace impurities can compromise consumer safety. Overuse of synthetic chemicals, particularly in highly processed foods, fuels public skepticism and amplifies calls for cleaner-label alternatives. Negative perception is also driven by misinformation and misunderstandings about the role of these substances, placing additional pressure on manufacturers to increase transparency and education. Moreover, supply chain inconsistencies - from fluctuating raw material quality to global logistics disruptions - pose challenges for maintaining consistent purity and compliance standards. Together, these issues highlight the need for more robust controls, better communication, and continuous innovation across the industry.

Purity: The Foundation of Next-Generation Food-Grade Chemicals

As the global food industry evolves, purity has become the central benchmark for assessing the quality and reliability of food-grade chemicals. With consumers demanding cleaner formulations and regulators enforcing tighter controls, manufacturers must now meet standards once reserved for pharmaceutical production. This shift is reshaping both expectations and technologies across the sector.

Stricter Global Regulations

Regulatory bodies worldwide are raising the bar for food-grade chemical purity. Agencies such as the FDA in the United States, EFSA in the European Union, and FSSAI in India are tightening allowable impurity limits, reinforcing traceability rules, and mandating more detailed safety documentation. Meanwhile, Codex Alimentarius, globally recognized as the international reference for food safety standards, is increasingly emphasizing transparent ingredient specifications and harmonized purity criteria to support cross-border trade. These trends collectively signal a transition toward globally unified expectations, making high-purity chemicals not just preferred but essential for compliance and market access.

Advances in Testing & Quality Assurance

Technological breakthroughs are revolutionizing how purity is measured and verified. AI-driven detection systems can now identify anomalies, contaminants, or specification deviations in real time, reducing human error and accelerating decision-making. Likewise, next-generation nano-sensors enable ultra-precise monitoring of trace impurities at parts-per-billion levels, providing unprecedented control over production processes. Together, these innovations allow manufacturers to maintain consistent quality even as standards become more demanding.

Rise of Ultra-Pure and Pharma-Grade Crossovers

The growing need for extreme purity is also blurring the lines between food-grade and pharmaceutical-grade chemicals. Industries are converging because both sectors depend on consistency, safety, and highly controlled manufacturing environments. As food companies adopt pharma-style quality systems - and as pharmaceutical firms expand into nutrition and functional food sectors - the demand for ultra-pure ingredients continues to rise. This crossover reinforces a new market reality: purity is no longer a differentiator but a non-negotiable foundation for future-focused food production.

Safety Innovations: How Technology Is Minimizing Risks

Safety has always been a core requirement in food-grade chemicals, but today’s technologies are transforming how risks are prevented, detected, and managed across the entire supply chain. From biosynthesis to blockchain, the industry is embracing smarter, cleaner, and more controlled methods to safeguard consumers while

supporting regulatory compliance.

Biosynthesized & Fermentation-Derived Additives

One of the most significant shifts in recent years is the move toward biosynthesized and fermentation-derived additives. Using precision fermentation, manufacturers can produce enzymes, organic acids, vitamins, flavors, and other functional ingredients with exceptionally high purity and consistent molecular structures. These biologically derived chemicals often eliminate impurities associated with traditional synthesis and reduce the need for harsh solvents or chemical intermediates. As a result, they minimize contamination risks, improve batch reliability, and align with the growing consumer preference for “naturally derived” ingredients.

AI & Machine Learning for Hazard Prediction

Artificial intelligence is becoming a powerful tool for enhancing safety in real time. Machine learning models can analyze vast datasets - from historical toxicity reports to molecular structures - to predict the potential hazards of new or existing chemicals. Predictive modeling helps manufacturers evaluate toxicity risks earlier in the development process, reducing costly trial-and-error and preventing unsafe products from reaching the market. AI-driven monitoring systems can also detect anomalies, cross-contamination threats, or deviations in production parameters before they escalate into safety issues.

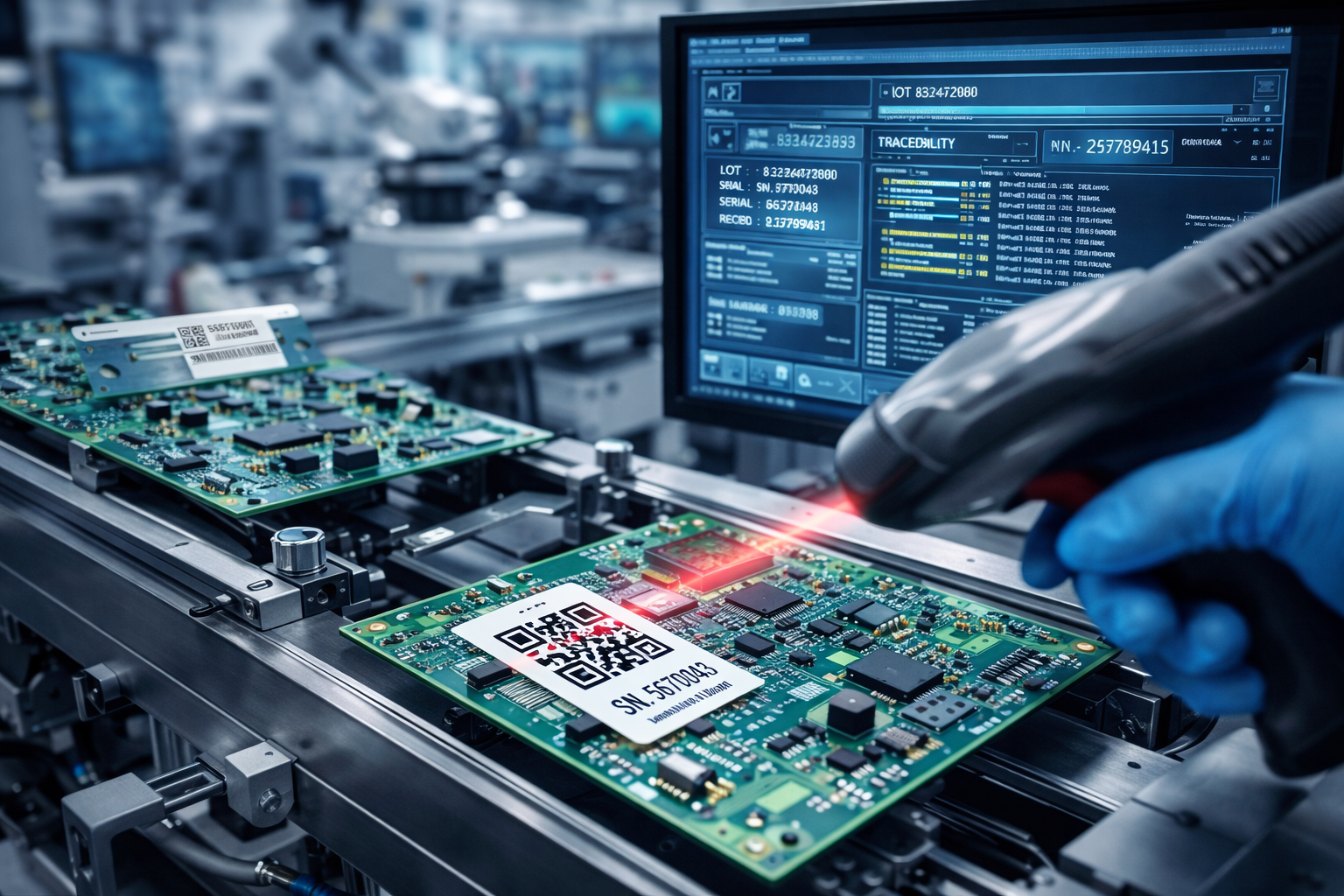

Transparent Labeling & Traceability Systems

With transparency now essential, advanced traceability tools are helping companies track every stage of a chemical’s journey. Blockchain, in particular, offers tamper-proof data records that document sourcing, processing, testing, and transportation. This level of traceability builds consumer trust, simplifies audits, and enhances recall efficiency if issues arise. As global supply chains grow more complex, these transparent systems ensure safety from raw materials to the final food product, setting a new standard for accountability in the

food-grade chemical sector.

Sustainability: The Biggest Catalyst for Change

Sustainability has become the most transformative force shaping the future of food-grade chemicals. With climate goals intensifying, resources becoming more constrained, and consumers demanding environmentally responsible products, manufacturers are rethinking not only what they produce but how they produce it. The shift toward greener chemistry is no longer optional - it is a fundamental requirement for long-term competitiveness and global market acceptance.

Renewable and Bio-Based Raw Materials

A growing portion of food-grade chemicals is now derived from renewable, plant-based sources rather than traditional petrochemicals. Plant-based solvents, bio-derived acids, and naturally sourced stabilizers reduce reliance on fossil fuels and lower overall carbon footprint. These materials also align with green chemistry principles, which prioritize energy efficiency, safe synthesis pathways, and non-toxic reagents. By adopting renewable feedstocks, manufacturers can improve sustainability metrics without compromising performance or purity.

Waste Reduction & Circular Production Models

Circular production models are reshaping how companies approach resource efficiency. Upcycling byproducts, from agricultural residues to fermentation leftovers, creates new streams of valuable food-grade ingredients. This reduces waste, decreases disposal costs, and supports circular chemistry practices that extend the life cycle of raw materials. Improved process integration, closed-loop water systems, and heat recovery technologies further minimize environmental impact while enhancing operational efficiency.

Biodegradable and Low-Impact Chemical Alternatives

As concerns about long-term ecological effects grow, the industry is moving toward biodegradable and low-impact food-grade chemicals. Eco-friendly preservatives, natural antimicrobial agents, and plant-derived cleaning compounds are becoming viable substitutes for their synthetic counterparts. These alternatives break down more easily in the environment and reduce the risk of harmful residues entering ecosystems. Combined with robust safety and purity standards, they enable manufacturers to deliver products that are both high-performing and environmentally responsible.

Together, these innovations position sustainability as the driving catalyst for change - steering the entire sector toward cleaner processes, renewable inputs, and a more circular, resilient future.

The Clean-Label Movement and Consumer-Driven Demand

The clean-label movement has become one of the most powerful forces reshaping the food-grade chemical landscape. Today’s consumers are more informed, more health-conscious, and more vocal about the ingredients in their food. As a result, manufacturers are under increasing pressure to deliver products that not only perform well but also appear simple, natural, and transparent. This shift is redefining how food-grade chemicals are selected, sourced, and formulated.

How Consumers Are Shaping Chemical Use

Modern consumers want shorter ingredient lists, familiar names, and formulations free from synthetic or potentially harmful additives. This demand for natural, non-toxic ingredients has led many food producers to replace traditional preservatives, colorants, and stabilizers with plant-derived or minimally processed alternatives. Transparency has become a key purchasing factor, with shoppers expecting clear labeling, ethical sourcing, and visible commitments to purity and sustainability.

Challenges for Manufacturers

For manufacturers, meeting clean-label expectations comes with significant hurdles. Reformulating recipes using natural alternatives often increases formulation complexity, as plant-based ingredients can behave differently or offer less stability than their synthetic counterparts. These substitutions can also increase production costs, requiring new supply chains, additional testing, or specialized processing conditions. Balancing performance, shelf life, and clean-label status remains a persistent challenge.

Opportunities for Innovation

Despite the obstacles, the clean-label trend is sparking major innovation. Natural colorants, from beetroot to spirulina, are replacing artificial dyes with vibrant, consumer-friendly alternatives. Plant-derived emulsifiers and stabilizers are opening pathways to more sustainable and functional food systems. As demand continues to grow, the clean-label movement is not just reshaping the ingredient landscape - it is driving new possibilities for safer, simpler, and more nature-aligned food-grade chemicals.

Case Studies: Leading Innovators in Sustainable Food-Grade Chemicals

Across the global food-ingredient sector, several forward-thinking companies are demonstrating how sustainability, purity, and safety can be advanced simultaneously through innovation. These industry leaders are proving that green chemistry is not only viable but also commercially strategic for the future of food-grade chemicals.

Many manufacturers are now adopting green chemistry principles to redesign production pathways. Some bio-ingredient producers have replaced petrochemical feedstocks with renewable plant-based materials, significantly reducing carbon intensity while maintaining high product performance. Others are utilizing enzymatic synthesis and fermentation routes to create food acids, flavors, and stabilizers with fewer byproducts, lower energy requirements, and improved purity profiles.

At the same time, cutting-edge companies are investing heavily in technologies that reduce emissions and enhance quality control. Advanced purification systems powered by membrane filtration, ion exchange, and energy-efficient crystallization are helping producers achieve ultra-low impurity levels while lowering water and energy consumption. Some innovators are integrating AI-driven monitoring tools that track carbon footprint, optimize reaction conditions, and prevent contamination in real time.

Together, these developments showcase how sustainable practices (once viewed as costly) are becoming key competitive advantages. By merging responsible sourcing, low-impact manufacturing, and next-generation quality technologies, these innovators are setting new standards for what the future of food-grade chemicals can and should look like.

Future Outlook: What the Next Decade Holds

The next decade will bring unprecedented transformation to the food-grade chemical industry, driven by scientific breakthroughs, digital automation, and the tightening of global safety and sustainability standards. As manufacturers work to balance purity, safety, and environmental responsibility, the future of food-grade chemicals will be shaped by technologies that are smarter, cleaner, and more interconnected than ever before.

Synthetic Biology and Lab-Grown Molecules

Synthetic biology is poised to redefine how food-grade chemicals are created. Lab-grown molecules, engineered enzymes, and precision-fermentation pathways will enable the production of highly consistent, ultra-pure ingredients without relying on traditional synthesis or resource-intensive extraction. These bio-engineered compounds can be designed for specific functionalities, such as enhanced stability or improved nutritional value, offering manufacturers tailored solutions with a significantly lower environmental footprint.

Autonomous Quality Control Systems

Automation will revolutionize quality assurance. AI-enabled sensors, real-time analytics, and autonomous monitoring systems will allow manufacturers to detect impurities, deviations, or contamination risks instantly - long before they can impact final products. These closed-loop systems will not only increase safety and purity but also reduce operational costs and human error. In the future, factories may operate with continuous self-verification, making quality control faster, more accurate, and fully integrated into production workflows.

Regulation-Driven Innovation & Global Standards Harmonization

Stricter global regulations are expected to accelerate innovation across the industry. As regions align their standards - driven by Codex Alimentarius, EFSA, FDA, and other global bodies - harmonized criteria for purity, testing, and sustainability will emerge. This alignment will simplify cross-border trade, elevate safety benchmarks, and encourage technologies that help companies meet these unified requirements. Ultimately, regulation-driven innovation will set the tone for a decade defined by cleaner processes, smarter compliance, and more responsible food-grade chemistry.

Conclusion – Toward a Pure, Safe and Sustainable Food Future

As food-grade chemicals enter a new era, purity, safety, and sustainability have become inseparable priorities guiding innovation across the industry. Advances in biosynthesis, AI-driven quality control, renewable raw materials, and circular production models are reshaping how manufacturers create and verify the ingredients that support global food systems. At the same time, consumer expectations for transparency and natural ingredient profiles are accelerating the clean-label movement, pushing companies to rethink long-standing formulation practices.

The path forward lies in adopting environmentally responsible chemicals that deliver high performance while minimizing ecological and health risks. By embracing green chemistry, investing in advanced testing technologies, and aligning with emerging international standards, the food industry can build a safer, smarter, and more sustainable future - one where quality and environmental stewardship move hand in hand.

FAQs

What makes a chemical “food-grade”?

A chemical is considered “food-grade” when it meets strict purity, safety, and quality standards set by regulatory bodies such as the FDA, EFSA, or Codex Alimentarius. These chemicals must be free from harmful contaminants, produced under controlled conditions, and proven safe for direct or indirect use in food processing.

Are natural additives always safer than synthetic ones?

Not necessarily. While natural additives can appeal to consumers and fit clean-label trends, safety depends on rigorous testing rather than the ingredient’s origin. Some natural compounds may cause allergies or instability, while many synthetic additives are highly purified, thoroughly studied, and tightly regulated.

How is sustainability measured in food chemicals?

Sustainability is evaluated by analyzing a chemical’s full life cycle, including raw material sourcing, carbon footprint, water and energy use, waste generation, and end-of-life impacts. Green chemistry principles, renewable feedstocks, and circular production models also contribute to sustainability assessments.

What new regulations are expected in the future?

The industry is moving toward stricter global standards on purity, traceability, and environmental impact. Regulations are expected to increasingly focus on ultra-low impurity limits, transparent labeling, sustainable sourcing, and harmonization of global safety criteria to support cross-border trade.

Are biodegradable food chemicals widely available yet?

Biodegradable alternatives, such as natural preservatives, plant-derived cleaners, and eco-friendly processing aids, are becoming more common, but availability varies by region and application. As demand grows and technology advances, biodegradable options are expected to expand rapidly across multiple food categories.