Understanding Calcium Nitrate: Key Benefits for Greenhouse and Hydroponic Agriculture

Calcium nitrate, with the chemical formula Ca(NO₃)₂, is a water-soluble compound composed of calcium and nitrogen - two essential nutrients for plant development. Often appearing as a colorless salt or granule, it has long been recognized for its effectiveness in boosting crop health and productivity. Its dual nutrient profile makes it especially valuable in agriculture: calcium strengthens plant cell walls, while nitrate nitrogen is readily absorbed, supporting vigorous growth.

Historically, calcium

nitrate was first used in agriculture in the early 20th century, primarily in regions with calcium-deficient soils. Over time, it became a staple in conventional farming, particularly for high-value crops like fruits and vegetables. As precision farming and controlled-environment agriculture have gained traction, calcium nitrate has re-emerged as a preferred fertilizer, especially in greenhouse and hydroponic systems.

Today, its popularity is growing rapidly thanks to its versatility and effectiveness in solving common nutrient deficiencies, preventing blossom end rot, and improving overall plant resilience. In modern farming practices where yield, efficiency, and plant health are crucial, calcium nitrate provides a reliable and targeted solution. This article explores its benefits, especially in controlled environments, where nutrient balance is key to maximizing crop performance.

Why Calcium Nitrate is Crucial in Plant Nutrition

Plants require a balanced supply of nutrients to thrive, and calcium nitrate delivers two critical ones:

- Calcium strengthens cell walls, improves fruit firmness and enhances overall plant structure.

- Nitrate nitrogen promotes chlorophyll production and vigorous

vegetative growth.

By supplying calcium in a form that’s easily absorbed by roots, calcium nitrate helps plants prevent common issues like:

- Blossom end rot in tomatoes and peppers

- Tip burn in lettuce

- Premature fruit drop in cucurbits

Calcium vs Other Nutrient Sources

Unlike calcium chloride or gypsum, calcium nitrate is fully water-soluble and compatible with other nutrients in fertigation or hydroponic systems. It doesn't increase salinity as much as some alternatives and avoids ammonia toxicity risks linked to ammonium-based fertilizers.

Advantages of Calcium Nitrate in Greenhouse Agriculture

Greenhouses offer a controlled environment that amplifies the benefits of calcium nitrate. Here's how it supports better outcomes:

- Faster Nutrient Uptake: Thanks to constant temperature and humidity control.

- Targeted Application: Calcium nitrate can be delivered directly to root zones via drip systems.

- Disease Resistance: Calcium fortifies plant tissues, making them less susceptible to pathogens.

- Higher Fruit Quality: Leads to firmer, longer-lasting produce.

Real-World Greenhouse Use Cases

In commercial tomato greenhouses, the use of calcium nitrate has been linked to a 15–20% increase in yield and a reduction in blossom end rot by 70%. Growers also report better shelf life and color consistency in market produce.

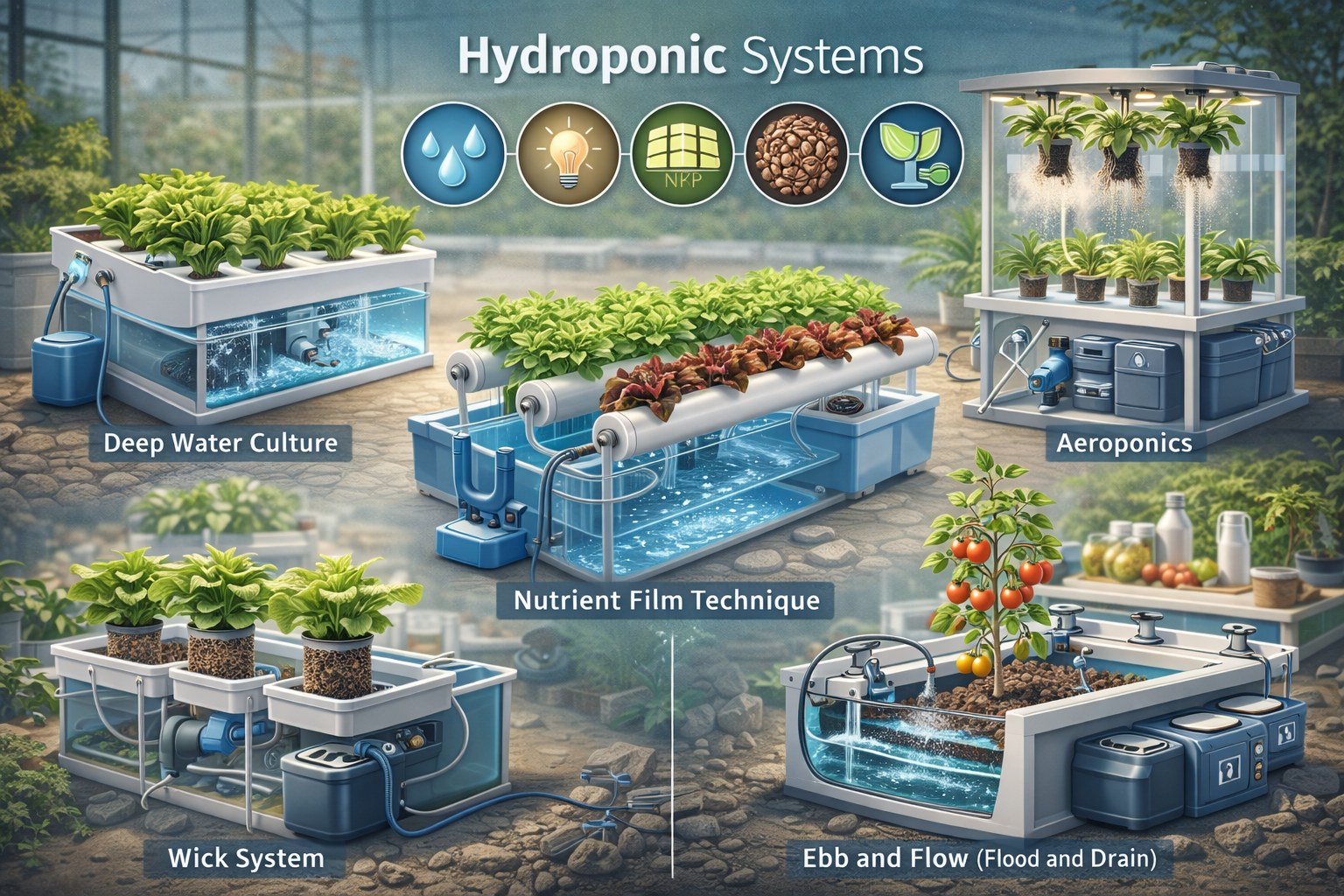

Benefits of Calcium Nitrate in Hydroponics

In hydroponic setups, nutrient management is critical. Calcium nitrate stands out due to:

- Complete Solubility: It dissolves fully without clogging lines.

- Fast Absorption: Nitrate nitrogen is quickly taken up by plants, aiding rapid growth.

- Calcium Deficiency Prevention: Fast-growing plants like lettuce and basil need constant calcium replenishment.

- Compatibility: Works seamlessly in multi-part nutrient regimens (e.g., 3-part or 2-part systems).

Dosage and Application Tips for Hydroponic Systems

- General Usage: 150–200 ppm calcium for leafy greens; 200–250 ppm for fruiting crops.

- Mixing Tip: Always dissolve calcium nitrate separately from phosphates and sulfates to avoid precipitation.

- pH Range: Ideal absorption occurs in the pH range of

5.8 to 6.2.

Hydroponic growers often use calcium nitrate alongside

magnesium sulfate (Epsom salt) and

potassium nitrate in A/B tank systems.

How to Apply Calcium Nitrate Effectively

Application methods vary by growing system:

- Fertigation (Greenhouses): Inject into drip irrigation systems; monitor EC and pH.

- Foliar Feeding: Useful during peak calcium demand phases, especially in flowering crops.

- Hydroponic Reservoirs: Add to nutrient tanks in measured ratios; use a TDS meter.

Common Mistakes to Avoid

- Mixing with incompatible nutrients (e.g., phosphates)

- Applying without testing the water pH

- Overdosing, which can lead to nitrate burn

Environmental and Economic Benefits

Calcium nitrate isn’t just good for plants - it’s also eco-smart:

- Low Leaching Risk: Especially in closed hydroponic systems.

- Better Nutrient Use Efficiency: More crop per unit of

fertilizer.

- Reduces Waste: Less fruit damage and spoilage means fewer losses.

- Sustainable Yields: Promotes healthier, more resilient plants over time.

It’s also cost-effective in the long run, thanks to higher yields, fewer diseases and better fruit quality.

Common Myths and Misconceptions

Let’s clear up some confusion around calcium nitrate:

- “It’s only for tomatoes.”

❌ False — It benefits a wide range of crops including peppers, strawberries, lettuce, and cucumbers. - “Too expensive for small farms.”

❌ Not true — Even small-scale hydroponic growers see ROI through better crop quality. - “It’s not organic.”

✅ While synthetic, it’s permitted in some certified hydroponic systems with proper labeling.

Frequently Asked Questions (FAQs)

Q1. Is calcium nitrate safe for hydroponic lettuce and herbs?

Yes, it is ideal for fast-growing greens and herbs. Just ensure it’s balanced with magnesium and potassium.

Q2. Can I mix calcium nitrate with magnesium sulfate?

Yes, but always in separate stock solutions to avoid precipitation.

Q3. What’s the ideal ppm for calcium in hydroponics?

Between 150–250 ppm depending on the crop and stage of growth.

Q4. How do I store calcium nitrate safely?

Keep in a dry, airtight container. It absorbs moisture quickly and can clump if left exposed.

Q5. Is it harmful to the environment?

Not when used correctly. In closed-loop hydroponic systems, there is minimal environmental impact.

Conclusion

Calcium nitrate is a powerful ally for modern growers using greenhouse or hydroponic techniques. By supplying essential calcium and nitrate nitrogen in an easily absorbable form, it promotes strong plants, healthy fruits and sustainable yields.

Whether you’re running a high-tech greenhouse or a simple hydroponic system at home, incorporating calcium nitrate into your nutrient plan can make a measurable difference.

Recommended Tools

- EC and pH Meter - For precise nutrient monitoring

- Hydrobuddy - Hydroponic Nutrient Calculator

- Hydroponic-Research.com - Fertilizer Mixing Guide