Nitrate Salts in Thermal Energy Storage: Powering Europe’s Renewable Future

As Europe accelerates its transition to renewable energy, wind and solar power are becoming increasingly central to national energy strategies. In 2024, over 40% of the EU’s electricity came from renewables — a milestone that reflects the continent’s commitment to decarbonization. Yet this rapid growth brings a major challenge: intermittency. What happens when the sun doesn't shine or the wind doesn't blow?

To ensure stability and efficiency in green energy systems, advanced energy storage solutions are essential. Among the most promising technologies is thermal energy storage (TES) — and at its core are nitrate salts, particularly in molten form. These substances can absorb, store and release vast amounts of thermal energy, making them ideal for storing excess renewable power and dispatching it when demand peaks.

Molten salt systems offer a compelling answer to Europe’s energy storage puzzle, with the potential to bridge supply gaps without carbon emissions. In this blog post, we’ll explore how nitrate salts work in TES, their advantages over other storage technologies, and why they may be key to securing Europe’s

renewable energy future.

What Are Nitrate Salts?

Nitrate salts are inorganic compounds formed from nitric acid and various metal cations. In thermal energy storage (TES), they are prized for their ability to absorb and retain heat at high temperatures without decomposing. Chemically, they consist of the nitrate ion (NO₃⁻) combined with metals such as sodium (Na⁺) or potassium (K⁺).

The most commonly used nitrate salts in TES applications are sodium nitrate (NaNO₃) and potassium nitrate (KNO₃). These can be used individually or blended into eutectic mixtures, which have lower melting points and improved thermal characteristics. A typical eutectic mixture might melt at around 220°C and remain stable up to 600°C, making it ideal for storing solar heat in Concentrated Solar Power (CSP) plants.

What makes nitrate salts particularly suitable for energy storage is their high specific heat capacity and thermal stability. They can store large amounts of energy as sensible heat during the day and release it at night or during cloudy periods — helping to smooth out the variability of renewable energy sources.

From an industrial perspective, nitrate salts are readily available, cost-effective and widely used in other sectors such as fertilizers and explosives. They also have a well-understood safety profile, though they must be handled carefully due to their oxidizing properties. When managed properly, they provide a robust and scalable solution to meet Europe’s growing demand for energy storage.

How Nitrate Salts Are Used in Thermal Energy Storage (TES)

Thermal Energy Storage (TES) systems store energy in the form of heat, enabling the supply of power when sunlight or wind is unavailable. One of the most efficient forms of TES is sensible heat storage, where energy is stored by raising the temperature of a material without changing its phase. Molten nitrate salts are especially effective in this application due to their high heat capacity and thermal stability.

In Concentrated Solar Power (CSP) plants, mirrors or lenses focus sunlight onto a central receiver, heating a fluid — often a mixture of sodium and potassium nitrate. These salts are heated to temperatures between 250°C and 600°C, transforming them into a molten state capable of storing massive amounts of thermal energy.

The TES system operates in two main phases:

- Charging: During peak solar hours, sunlight heats the molten salt, which is then stored in an insulated "hot" tank.

- Discharging: When energy demand rises or solar input falls, the hot salt is pumped through a heat exchanger to produce steam, which drives turbines to generate electricity. The cooled salt is then returned to a "cold" tank, ready for reheating.

This closed-loop system enables continuous power generation, even at night or during overcast periods. Molten salt TES can also be integrated with other renewable sources, such as wind or excess grid electricity, allowing for hybrid storage solutions.

By stabilizing output and decoupling generation from immediate consumption, nitrate salt-based TES systems address one of the major hurdles of renewable energy:

intermittency. Their scalability, efficiency and compatibility with existing infrastructure make them a cornerstone technology for Europe’s clean energy future.

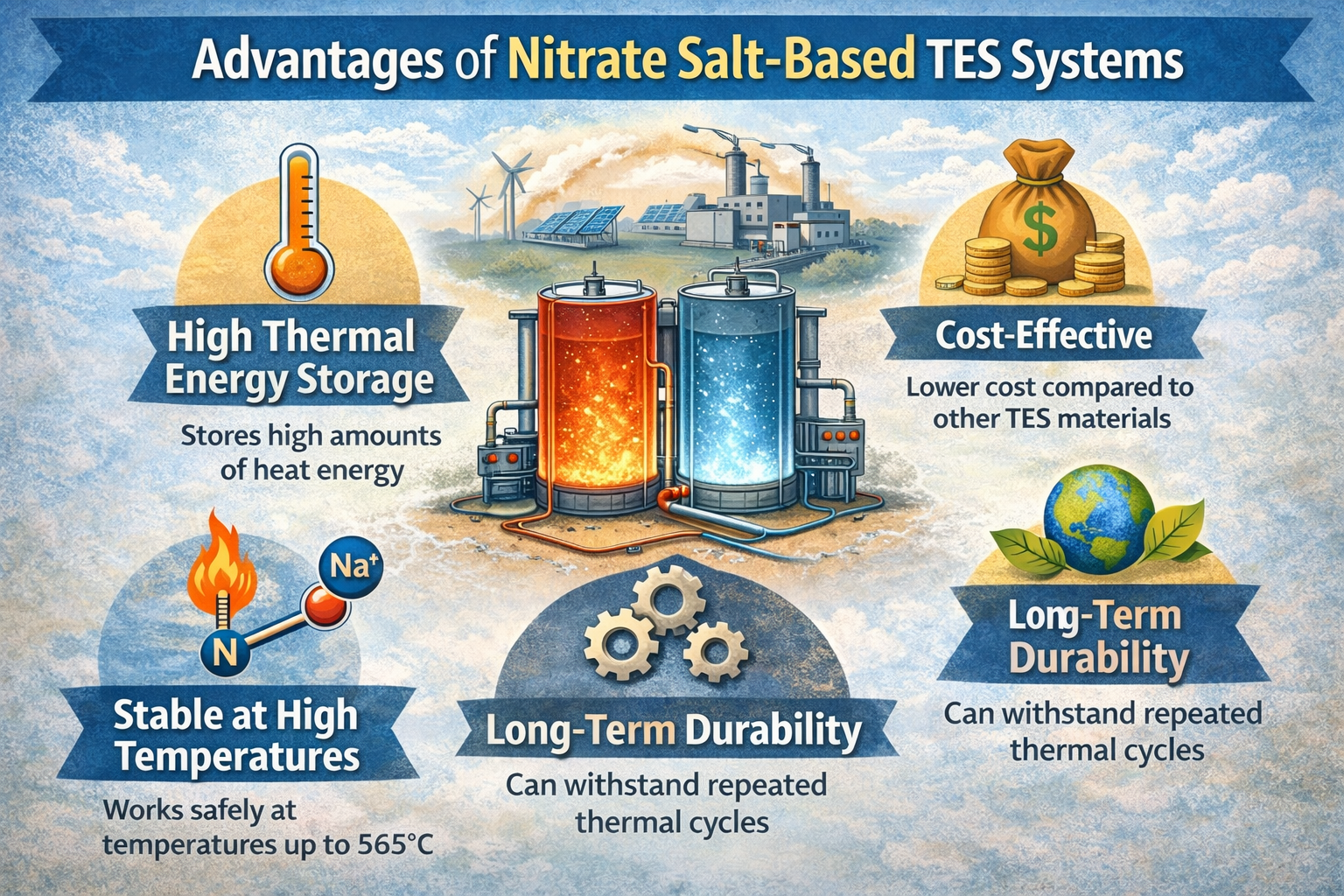

Advantages of Nitrate Salt-Based TES Systems

Nitrate salt-based thermal energy storage (TES) systems offer a powerful combination of technical performance, cost-effectiveness and environmental sustainability, making them a key enabler of the renewable energy transition.

One of their most significant advantages is high thermal stability. Molten nitrate salts can operate reliably at temperatures up to 600°C without degrading, allowing them to store large amounts of heat with excellent energy density. This makes them particularly well-suited for long-duration storage, providing several hours — or even days — of energy supply with minimal thermal loss in well-insulated systems.

In terms of economics, nitrate salts are relatively low-cost and widely available, as they are already produced at industrial scale for use in fertilizers and other applications. Their proven track record in industries outside of energy makes them a mature and readily scalable solution, requiring no exotic materials or rare resources.

Nitrate salt TES systems are also modular, allowing for straightforward expansion to meet growing energy demands. From utility-scale CSP plants to hybrid renewable systems, they can be integrated into a wide range of infrastructure with minimal disruption.

Importantly, these systems contribute to a reduced carbon footprint. Unlike battery-based storage, which depends on mining-intensive materials, nitrate salts are less environmentally taxing and offer a clean, long-lasting method for balancing renewable energy supply and demand.

In short, nitrate salt-based TES is a practical, sustainable technology that aligns with Europe’s goals for a greener, more resilient energy future.

Europe’s Renewable Energy Ambitions and the Role of TES

Europe has set ambitious goals to decarbonize its energy system and lead the global transition to clean power. Initiatives such as the EU Green Deal, Fit for 55 and REPowerEU aim to reduce greenhouse gas emissions by at least 55% by 2030 and achieve climate neutrality by 2050. Central to these plans is the massive scaling-up of renewable energy, particularly wind and solar. However, both sources are inherently intermittent — the sun doesn’t always shine, and the wind doesn’t always blow — creating a pressing need for reliable energy storage solutions.

Thermal Energy Storage (TES) using nitrate salts offers a compelling way to address this challenge. By storing excess heat generated during peak renewable production hours and releasing it when demand rises, TES systems can stabilize the grid and reduce reliance on fossil fuel backup.

Several European countries are already investing in TES deployment. In Spain, large-scale Concentrated Solar Power (CSP) plants with molten salt storage, such as the Gemasolar facility, are delivering dispatchable solar energy 24/7. Germany has explored integrating TES into industrial heating and district energy systems, while Denmark is piloting TES with renewable electricity to decarbonize heating networks.

Policy support is also gaining momentum. EU funding programs like Horizon Europe and the Innovation Fund are allocating resources for TES research, development and demonstration projects. National governments are beginning to recognize TES as a strategic technology in the broader green transition.

As Europe races toward its renewable energy targets, nitrate salt-based TES systems will play a crucial role in delivering flexibility, reliability and sustainability, helping turn ambitious climate goals into everyday reality.

Challenges and Limitations of Nitrate Salt Storage

While nitrate salt-based thermal energy storage (TES) offers many advantages, several technical and operational challenges must be addressed to ensure long-term performance and safety.

One of the primary concerns is corrosion. Molten nitrate salts, especially at high temperatures, can be corrosive to common construction materials such as carbon steel. Specialized alloys or corrosion-resistant coatings are often required, which can increase capital costs and complicate system design. Ensuring material compatibility over years of thermal cycling is critical to system reliability.

Another challenge lies in the freezing point of nitrate salts. Most nitrate mixtures solidify between 120°C and 220°C. If the salt cools below this temperature, it can crystallize and block pipes or damage components. To prevent this, systems must include active heat tracing and insulation, adding complexity and energy consumption to the infrastructure.

From an environmental and safety standpoint, while nitrate salts are less hazardous than many alternatives, they are oxidizing agents and must be handled with care to prevent fire risks and accidental releases. Proper storage, monitoring and emergency protocols are essential, particularly for large-scale installations.

Lastly, the long-term stability of nitrate salts and the overall life cycle impacts of TES systems require further research. While these systems can operate for decades, salt degradation, thermal fatigue in components and eventual disposal must be considered in sustainability assessments.

Despite these limitations, continued innovation in materials science, engineering design and safety practices is helping to mitigate these risks — keeping nitrate salt TES a viable and evolving technology for clean energy storage.

Emerging Innovations and Future Outlook

As Europe advances toward a more renewable-powered future, ongoing innovations in nitrate salt-based thermal energy storage (TES) are addressing current limitations and expanding the technology’s potential.

One promising area is the development of hybrid salt technologies, such as chloride-nitrate blends. These mixtures aim to lower costs and increase operating temperatures, enhancing system efficiency while reducing reliance on more expensive nitrate salts. Although chlorides present greater corrosion risks, new corrosion-resistant materials and coatings are being explored to make these blends viable for long-term use.

Simultaneously, advances in reactor materials and insulation techniques are boosting system durability and energy retention. High-performance ceramics, composite materials and improved tank linings are extending the lifespan of TES components and reducing maintenance needs, making grid-scale deployment more economically attractive.

Europe is at the forefront of these innovations, with numerous R&D consortia, universities, and private companies collaborating under EU programs like Horizon Europe. Pilot projects across the continent are testing next-generation TES systems, with strong support from both public funding and industrial partnerships.

Looking ahead, nitrate salts are poised to play a central role in grid-scale energy storage, especially when paired with concentrated solar power and surplus renewable electricity. As costs fall and system performance improves, these technologies will become even more attractive for utilities and policymakers seeking reliable, low-carbon energy solutions.

With continued investment and innovation, nitrate salt-based TES is well positioned to help stabilize Europe's renewable grid, turning clean energy into a 24/7 reality.

FAQs – Nitrate Salts in Thermal Energy Storage

What are the main advantages of nitrate salts over batteries?

Nitrate salt-based thermal energy storage (TES) systems are more cost-effective and scalable than most battery technologies, especially for long-duration storage. They have a longer operational lifespan, lower environmental impact and avoid reliance on rare or toxic materials. Unlike batteries, they store energy as heat, making them ideal for integration with solar thermal power and industrial heat applications.

Are nitrate salts safe for long-term storage?

Yes, when properly managed, nitrate salts are safe for long-term use. They are non-flammable and chemically stable at high temperatures. However, they are oxidizing agents and must be handled with care to prevent environmental contamination or fire risk. TES facilities are designed with strict safety protocols, monitoring systems and containment measures.

How long can energy be stored using nitrate salts?

Thermal energy can be stored in molten nitrate salts for up to several days with minimal heat loss, depending on insulation and system design. This makes them highly effective for balancing daily fluctuations in renewable energy supply and demand.

Which countries in Europe are leading in nitrate salt TES?

Spain is the European leader, with several large-scale concentrated solar power (CSP) plants using molten salt storage. Germany, Denmark, and Italy are also advancing TES technologies through pilot projects and industrial integration.

Can nitrate salts work in cold climates?

Yes, but additional infrastructure is needed. Since nitrate salts solidify at relatively high temperatures, heat tracing and insulation are required to prevent freezing in colder environments. With proper design, TES systems can be effectively deployed even in northern Europe.

Conclusion

As Europe accelerates its transition to renewable energy, nitrate salt-based thermal energy storage (TES) stands out as a practical, efficient, and sustainable solution for overcoming intermittency challenges. With their high thermal stability, long storage duration, and cost-effectiveness, nitrate salts enable reliable energy supply even when wind or solar generation dips.

These systems are already proving their value in countries like Spain and Germany, offering scalable, grid-ready storage that aligns perfectly with the EU’s Green Deal and Fit for 55 objectives. Their industrial readiness and compatibility with both existing and emerging renewable infrastructure make them a strategic asset in Europe’s clean energy future.

Looking ahead, continued innovation in salt blends, materials science, and system design will further enhance performance and reduce costs. The synergy between public policy, research funding and private-sector development is driving this technology forward — ensuring that sustainability and reliability go hand in hand.

Nitrate salts may not be the flashiest solution in the energy sector, but their impact is profound: quietly storing the sun’s heat and powering Europe toward a greener, more resilient future.

As the demand for high-quality nitrates grows, companies like

DECACHEM play a vital role in ensuring reliable supply. As one of Europe’s main distributors of technical and food-grade nitrates, DECACHEM supports the energy sector with consistent, high-purity materials essential for the expansion of thermal storage systems across the continent.