Why Potassium Nitrate Is Essential for High-Yield Fertilizers in Modern Agriculture

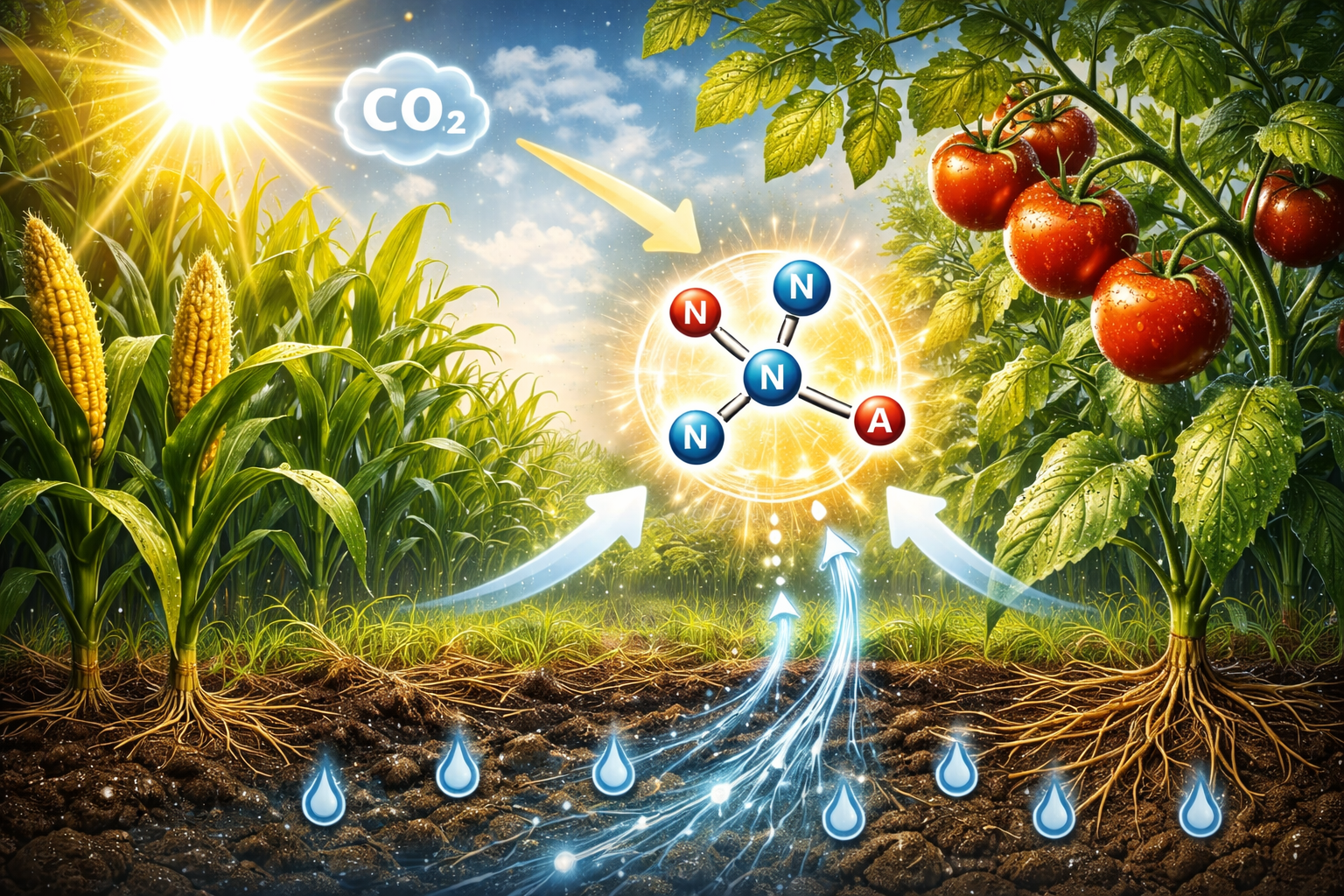

Potassium nitrate (KNO₃) is a highly efficient and widely used fertilizer component in modern agriculture. It combines two of the most essential macronutrients required for plant growth - potassium (K) and nitrogen (N) - in a form that is readily soluble in water and easily absorbed by plants. As global demand for food continues to rise, driven by population growth and the need for sustainable farming, potassium nitrate has become a key ingredient in high-yield fertilizer formulations.

Chemically composed of one potassium ion (K⁺) and one nitrate ion (NO₃⁻), potassium nitrate serves a dual purpose in plant nutrition. Potassium is crucial for overall plant health, as it helps regulate water uptake, strengthen cell walls, and enhance resistance to disease and environmental stress. Nitrate, on the other hand, is a vital source of nitrogen - an element central to chlorophyll production, protein synthesis and vegetative growth.

What makes potassium nitrate particularly valuable is its compatibility with precision agriculture and fertigation systems, allowing farmers to deliver balanced nutrients directly to plant roots. This targeted approach not only enhances crop yields but also minimizes environmental impact. In this post, we’ll explore why potassium nitrate is indispensable for achieving optimal agricultural productivity sustainably and efficiently.

Importance of Nutrients in Plant Growth

Plants, like all living organisms, require a balanced diet of nutrients to grow, develop and produce high yields. These nutrients are broadly categorized into macronutrients and micronutrients. Macronutrients, such as nitrogen (N), phosphorus (P), and potassium (K), are required in large quantities and play a crucial role in plant metabolism and structure. Micronutrients, including iron, zinc, manganese and copper, are required in smaller amounts but are equally vital for enzyme activation, photosynthesis, and overall plant health.

Among macronutrients, potassium and nitrogen are especially important for optimizing growth. Potassium regulates essential physiological processes, including water use efficiency, enzyme activation and stress resistance. It also contributes to the development of strong stems and the transport of sugars throughout the plant. Nitrate nitrogen, a form of nitrogen readily absorbed by roots, supports vigorous vegetative growth and is a key component of amino acids and proteins.

When combined in the form of potassium nitrate, these two elements create a synergistic effect that boosts crop performance. This balanced nutrient supply enhances root development, flowering and fruiting, leading to higher quality and quantity of yield. By ensuring plants receive both potassium and nitrate nitrogen in the right proportions, farmers can achieve consistent and sustainable agricultural productivity.

Key Benefits of Potassium Nitrate in Fertilizers

Potassium nitrate is more than just a source of essential nutrients - it’s a strategic component in advanced fertilizer formulations that supports healthy plant development and high-yield outcomes. Its unique combination of potassium and nitrate nitrogen delivers a powerful range of agronomic benefits.

Enhances Root and Shoot Development

Potassium nitrate significantly contributes to the early stages of plant growth by promoting strong root and shoot systems. A well-developed root system allows plants to anchor themselves securely in the soil and explore a wider soil volume for water and nutrients. This leads to better nutrient acquisition and increased resistance to transplant shock. Meanwhile, potassium supports the transport of carbohydrates from leaves to growing tissues, which enhances shoot vigor and overall crop establishment. The result is a more robust plant structure capable of supporting higher yields.

Boosts Photosynthesis and Water Regulation

Potassium plays a vital role in photosynthesis, not only by activating key enzymes but also by regulating the opening and closing of stomata - the pores on leaf surfaces. Proper stomatal function is crucial for maintaining gas exchange and controlling water loss. By facilitating these processes, potassium nitrate improves a plant’s ability to photosynthesize efficiently, even under stressful conditions. Furthermore, enhanced stomatal regulation boosts water-use efficiency, making crops more tolerant to drought and reducing the risk of water-related stress during critical growth stages.

Improves Nutrient Uptake Efficiency

Nitrate nitrogen, the nitrogen form in potassium nitrate, is highly mobile in soil and readily absorbed by plant roots. This form of nitrogen acts quickly to stimulate vegetative growth and supports protein synthesis without acidifying the root zone. Additionally, potassium nitrate is fully water-soluble, making it ideal for fertigation and precision agriculture. Its compatibility with irrigation systems allows farmers to deliver nutrients directly to the root zone, optimizing uptake and minimizing nutrient losses due to leaching or volatilization.

Together, these advantages make potassium nitrate an essential input for efficient, sustainable and high-performance fertilization programs in modern agriculture.

How Potassium Nitrate Supports High Crop Yields

Potassium nitrate is widely recognized not only for enhancing plant growth, but also for directly contributing to higher and more consistent crop yields. Its balanced nutrient composition plays a vital role in improving both the quantity and quality of agricultural output.

Yield Improvements Backed by Research

Numerous studies have demonstrated the positive impact of potassium nitrate on crop performance. In tomatoes, for instance, potassium nitrate application has been shown to increase fruit size, weight and uniformity, while also improving sugar content - key factors for market value. In corn, trials have reported higher kernel weight and starch accumulation, leading to greater overall yield per hectare. Similarly, in wheat, potassium nitrate improves grain filling and boosts protein content, which is essential for both nutritional value and baking quality.

Beyond just yield volume, potassium nitrate contributes to better harvest quality. Nitrate nitrogen promotes efficient nutrient uptake and rapid growth, while potassium ensures the proper transport of sugars and starches, resulting in crops with higher concentrations of desirable compounds such as sugars in fruits, starch in tubers and grains, and proteins in cereals and legumes.

Reduced Incidence of Crop Diseases

One of the lesser-known but highly valuable benefits of potassium nitrate is its role in plant defense. Potassium strengthens cell walls, making plant tissues more robust and less prone to mechanical damage or pathogen penetration. This structural reinforcement reduces the susceptibility of crops to fungal and bacterial infections.

In particular, potassium-deficient plants are known to be more vulnerable to diseases like powdery mildew, blight and leaf spot. By ensuring an adequate potassium supply through fertilizers like potassium nitrate, farmers can promote healthier, more resilient crops with a reduced need for chemical treatments. This not only supports higher yields but also aligns with sustainable farming practices by lowering dependency on pesticides and improving crop longevity in the field.

Application Methods in Modern Agriculture

To fully harness the benefits of potassium nitrate (KNO₃), it's essential to apply it using methods that align with modern, efficient agricultural practices. Thanks to its high solubility and compatibility with various delivery systems, potassium nitrate is a versatile input suitable for both large-scale operations and precision farming.

Fertigation and Drip Irrigation

One of the most effective ways to apply potassium nitrate is through fertigation - delivering nutrients directly to the plant’s root zone via irrigation systems. Because KNO₃ is highly water-soluble and free of harmful residues, it dissolves quickly and completely, making it an ideal choice for use in drip and micro-irrigation systems.

In fertigation setups, potassium nitrate allows for precise nutrient management. Growers can adjust concentrations according to crop stages, ensuring optimal nutrient availability when plants need it most. This method also reduces nutrient losses due to leaching and volatilization, increasing the overall efficiency of fertilizer use. Moreover, fertigation with KNO₃ supports sustainable farming by conserving water and minimizing environmental impact.

Foliar Sprays and Top Dressing

In addition to root-zone applications, potassium nitrate can be used as a foliar spray - applied directly to plant leaves - for quick nutrient absorption. This method is particularly useful during critical growth stages or when rapid correction of nutrient deficiencies is needed. Foliar feeding ensures nutrients are quickly assimilated, leading to visible improvements in plant vigor within days.

Top dressing, where potassium nitrate is applied to the soil surface around plants, is another common technique, especially in field crops. This method supports steady nutrient availability and is often used to supplement the main fertilization plan.

For best results, it’s important to follow dosage recommendations based on crop type, growth stage and soil conditions. Over-application should be avoided to prevent nutrient imbalances, while under-application may limit yield potential. With the right approach, potassium nitrate delivers powerful benefits through flexible and efficient application methods.

Potassium Nitrate vs. Other Fertilizers

When choosing a fertilizer, it's important to consider not just nutrient content but also how it interacts with the soil, crops and the environment. Potassium nitrate (KNO₃) offers several advantages over other commonly used fertilizers such as potassium chloride (KCl), urea and ammonium nitrate.

Unlike potassium chloride, which contains chloride ions that can be harmful to chloride-sensitive crops like tobacco, potatoes and some fruits, potassium nitrate is chloride-free and safe for a wide range of crops. It delivers potassium in a cleaner form, reducing the risk of salt stress and toxicity.

Compared to urea and ammonium nitrate - two widely used nitrogen fertilizers - KNO₃ provides nitrogen in the nitrate (NO₃⁻) form, which is immediately available for plant uptake. Urea requires enzymatic conversion in the soil, which can lead to nitrogen losses through volatilization. Ammonium nitrate, while effective, can acidify the soil over time and poses regulatory and handling concerns due to its explosive potential.

In terms of environmental impact, potassium nitrate stands out as a low-risk, water-soluble option that supports efficient nutrient use and minimizes leaching when applied properly. Its compatibility with modern delivery systems and sensitive crops makes it a superior choice for sustainable, high-performance agriculture.

Sustainable Agriculture and KNO₃

As sustainability becomes a priority in global agriculture, potassium nitrate (KNO₃) stands out as an eco-friendly fertilizer choice that supports both productivity and environmental stewardship. One of its key advantages is its low salt index compared to other potassium and nitrogen fertilizers. This means it causes minimal salt buildup in the soil, reducing the risk of root damage and maintaining healthy soil structure over time.

Because KNO₃ is chloride-free and does not acidify the soil, it helps preserve long-term soil fertility - an essential factor for sustainable crop rotation and continuous farming. Its high nutrient-use efficiency also means fewer inputs are required to achieve desired yields, which translates to lower environmental impact through reduced runoff and leaching.

By supporting efficient water use, minimizing chemical residues, and promoting soil health, potassium nitrate aligns well with modern sustainable agriculture practices aimed at feeding the world while protecting natural resources for future generations.

Industry Applications and Trends

Potassium nitrate (KNO₃) has become a cornerstone in modern agriculture, particularly within greenhouse farming, hydroponics and precision agriculture. Its unique properties align well with the evolving needs of these sectors.

Use in Greenhouse Farming and Hydroponics

In controlled environments like greenhouses and hydroponic systems, potassium nitrate is highly valued for its complete solubility and balanced nutrient profile. It provides essential potassium and nitrate nitrogen without introducing chloride, which can be detrimental to sensitive crops. This makes it ideal for recirculating systems, as it prevents salt accumulation and maintains nutrient balance, promoting healthy plant growth and optimizing yields.

Growing Adoption in Precision Agriculture

The rise of precision agriculture has further amplified the use of potassium nitrate. Its compatibility with fertigation and variable-rate application technologies allows for precise nutrient delivery, enhancing crop performance while minimizing environmental impact. By supplying readily available nitrate nitrogen and potassium, KNO₃ supports the 4R nutrient stewardship principles - applying the right source at the right rate, time and place.

Market Trends and Projections

The global potassium nitrate market is experiencing steady growth, driven by increasing demand in sustainable and high-efficiency farming practices. Valued at approximately USD 5.70 billion in 2024, the market is projected to reach USD 7.45 billion by 2032, growing at a CAGR of 3.4%. This upward trend reflects the fertilizer's expanding role in meeting the challenges of modern agriculture, including the need for higher yields, resource efficiency and environmental sustainability.

FAQs

What crops benefit most from potassium nitrate?

Potassium nitrate is beneficial for a wide variety of crops, especially those sensitive to chloride or with high potassium and nitrogen demands. These include fruits and vegetables such as tomatoes, peppers, cucumbers and melons, as well as high-value crops like tobacco, grapes, coffee and potatoes. Cereal crops like corn and wheat also benefit from KNO₃, particularly during key developmental stages when nutrient uptake is critical for yield and quality.

Is potassium nitrate safe for organic farming?

While potassium nitrate is naturally occurring and safe for many crops, it is not approved for certified organic farming under most organic standards, including USDA and EU regulations. Organic farming requires nutrient sources derived from natural, minimally processed materials. However, KNO₃ is widely accepted in conventional and sustainable farming systems for its efficiency and low environmental impact.

Can potassium nitrate be mixed with other fertilizers?

Yes, potassium nitrate is highly compatible with many other fertilizers, particularly those used in fertigation and foliar applications. However, it should not be mixed with calcium-containing fertilizers (like calcium nitrate) in the same solution, as this may cause precipitation. Always check compatibility charts or perform a jar test before mixing.

What’s the ideal N:K ratio in crops like tomato, pepper, corn?

The optimal nitrogen-to-potassium (N:K) ratio varies by crop and growth stage. In general:

- Tomato and pepper: 1:1.5 to 1:2 during fruiting stages

- Corn: 1:1 during early vegetative growth, shifting to 1:1.2 or higher during grain filling

Balancing this ratio with potassium nitrate helps maximize both yield and crop quality.

Conclusion

Potassium nitrate is a vital fertilizer ingredient that delivers essential potassium and nitrate nitrogen in a highly efficient, chloride-free form. Its unique benefits - from enhancing root development to improving nutrient uptake - make it indispensable for boosting crop yields sustainably. By supporting precision agriculture and minimizing environmental impact, potassium nitrate plays a key role in meeting the growing global demand for food. DECACHEM, as one of the leading regional distributors of high-quality potassium nitrate and other nitrates, is proud to contribute to modern farming solutions that promote productivity and long-term soil health.