Greener Chemistry: Innovations in Nitrate Production

Nitrates play a vital role across various industries - from fertilizers that boost global agricultural output to essential components in pharmaceuticals, food preservation and explosives. Their versatility and effectiveness have made them indispensable in both the industrial and agricultural sectors. However, the traditional methods of nitrate production often come with significant environmental costs, including high energy consumption, greenhouse gas emissions and water pollution.

As the global demand for nitrates grows, it’s about time to address these ecological challenges. This is where the principles of greener chemistry come into play. By rethinking how nitrates are synthesized, processed and applied, researchers and manufacturers are pioneering innovative, more sustainable approaches. In this article, we explore how greener chemistry is transforming nitrate production, reducing environmental impact, while maintaining the high performance that industries rely on.

Why Traditional Nitrate Production Is Unsustainable

Conventional nitrate production relies heavily on processes that are both energy - intensive and environmentally damaging. One of the most commonly used methods is the Ostwald process, where ammonia is oxidized to produce nitric acid - a key precursor to many nitrate-based compounds. This process requires high temperatures and pressures, consuming vast amounts of energy, typically derived from fossil fuels. As a result, it contributes significantly to industrial carbon emissions.

A major byproduct of the Ostwald process is nitrous oxide (N₂O), a greenhouse gas nearly 300 times more potent than carbon dioxide in terms of global warming potential. Despite efforts to capture or decompose N₂O, a considerable amount still escapes into the atmosphere from production facilities worldwide.

Beyond greenhouse gas emissions, traditional nitrate manufacturing generates hazardous industrial waste, posing risks to both workers and surrounding communities. The handling and storage of reactive intermediates also raise safety concerns, including risks of fire, explosion, and chemical exposure.

Environmental Impacts of Conventional Methods

The environmental consequences of traditional nitrate production extend beyond emissions. Water contamination is a major issue, as nitrate-rich runoff from industrial sites or excessive fertilizer use can leach into groundwater, posing health risks such as methemoglobinemia (“blue baby syndrome”).

Air pollution is another concern. Apart from N₂O, nitric acid production can release nitrogen oxides (NOₓ), which contribute to smog formation and acid rain.

Furthermore, the overuse of synthetic nitrates in agriculture can lead to soil degradation, disrupting microbial ecosystems and reducing long-term fertility. These combined impacts underscore the need for a more sustainable approach - one that prioritizes environmental stewardship without compromising industrial performance.

What Is Greener Chemistry?

Greener chemistry, also known as green chemistry, is an innovative approach to chemical research and manufacturing that seeks to minimize environmental impact and enhance safety throughout a chemical's life cycle. At its core are the 12 principles of green chemistry, which include reducing waste, using safer solvents and reagents, improving energy efficiency, designing for degradation and shifting to renewable feedstocks. These principles promote cleaner production methods that are not only environmentally responsible but also economically viable.

When applied to nitrate chemistry, greener chemistry involves rethinking how nitrates are produced, processed and applied. For example, instead of relying on energy-intensive methods like the Ostwald process powered by fossil fuels, greener approaches aim to use renewable energy sources, catalytic efficiencies and biological alternatives to lower emissions and reduce waste.

This shift represents more than a technological upgrade - it’s a fundamental transformation in how the chemical industry operates. By embracing greener chemistry, manufacturers can reduce their

carbon footprint, limit hazardous byproducts like

nitrous oxide, and support a

more sustainable future for industries and ecosystems alike. As demand for low-impact solutions grows, green chemistry offers a clear path forward for modern nitrate production.

Breakthrough Innovations in Green Nitrate Production

As sustainability becomes a top priority across the chemical industry, researchers and innovators are developing new methods for nitrate production that align with the principles of green chemistry. These breakthroughs not only reduce harmful emissions and energy consumption, but also open new pathways for using renewable resources and waste materials efficiently. Below are some of the most promising innovations reshaping nitrate manufacturing.

Catalytic Oxidation with Reduced Emissions

Traditional catalytic oxidation processes release substantial amounts of nitrous oxide (N₂O), a powerful greenhouse gas. Recent advancements in zeolite-supported catalysts and other advanced materials have significantly reduced these emissions. These catalysts offer improved selectivity and stability during the oxidation of ammonia, limiting the formation of N₂O without sacrificing efficiency.

For example, iron- or copper-exchanged zeolites have shown promising results in laboratory settings, achieving high conversion rates of ammonia to nitric oxide with minimal byproduct formation. These developments offer a scalable solution for retrofitting existing plants and reducing their environmental impact without overhauling core infrastructure.

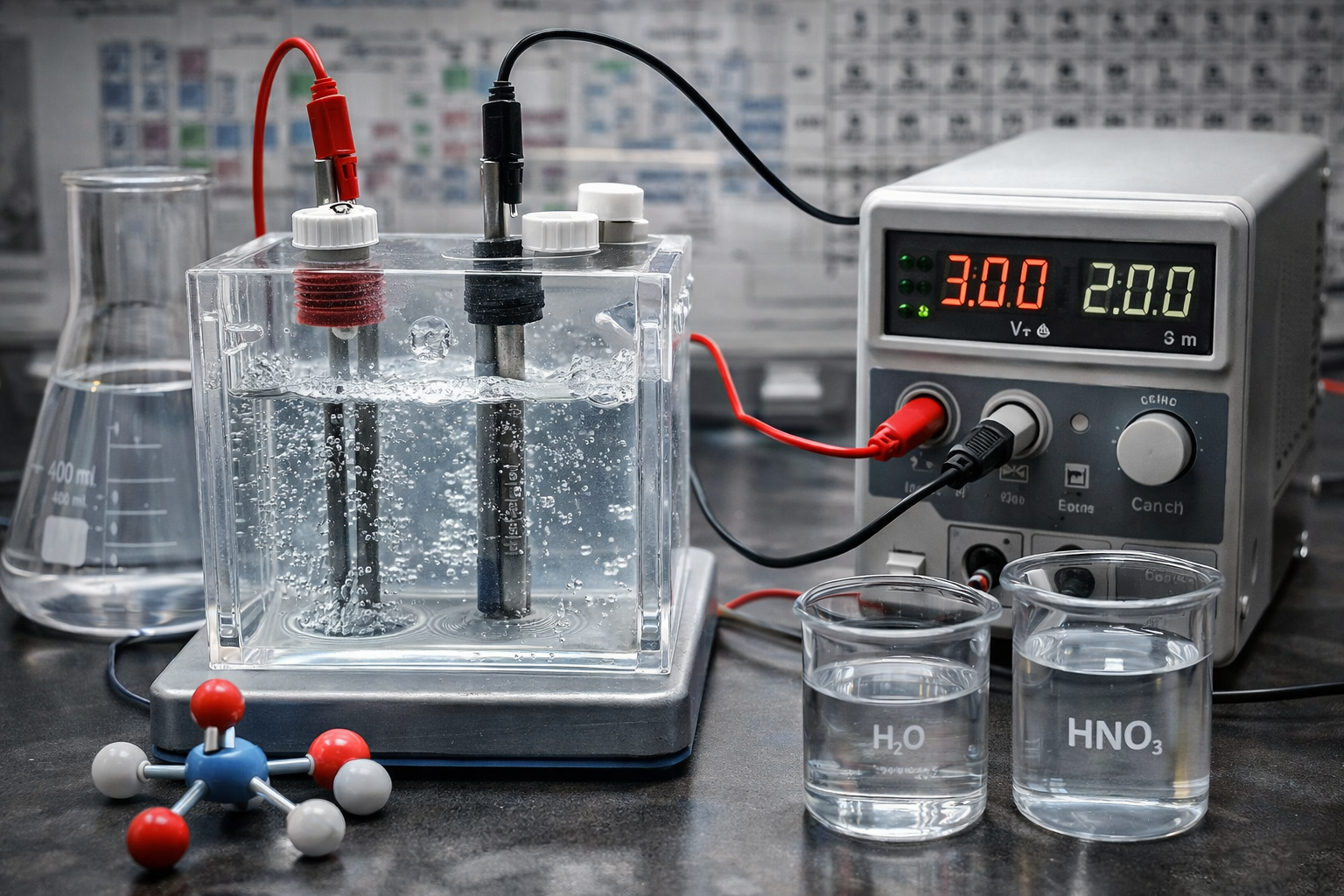

Electrochemical Nitrate Synthesis

Electrochemical methods are emerging as a game-changer for nitrate production. These systems use renewable electricity, such as solar or wind power, to drive the oxidation of nitrogen species, enabling decentralized and low-emission nitrate synthesis.

Notable academic research - such as work conducted at

ETH Zurich and

MIT - has demonstrated the feasibility of converting atmospheric nitrogen or ammonia into nitrates using electrochemical cells. These techniques eliminate the need for high-temperature reactors, significantly reducing

energy input and emissions. With further optimization, electrochemical synthesis could enable on-demand, localized nitrate production for industrial and agricultural applications, cutting down on transportation and storage emissions as well.

Biological and Enzymatic Pathways

Another promising area is the use of biocatalysts and engineered microbes to convert nitrogen into nitrates. This approach mimics natural nitrate cycling processes and requires much lower energy inputs than conventional methods.

Engineered bacteria and enzymes can facilitate nitrification under controlled conditions, offering a biologically inspired, low-impact alternative to chemical synthesis. While still in early development, these methods could eventually lead to sustainable nitrate production systems that integrate seamlessly into agroecological or waste treatment environments.

Integration with Circular Economy

Greener nitrate production also involves closing material loops by integrating with the circular economy. One example is the recovery of nitrogen-rich waste streams, such as from livestock operations, wastewater treatment, or industrial emissions, and upcycling them into useful nitrates.

Advanced separation and purification technologies now allow for the extraction and conversion of these waste nitrogen compounds, reducing environmental pollution while creating value-added products. This not only cuts down on raw material use but also aligns with broader sustainability goals by minimizing waste and promoting resource efficiency.

Industry Examples & Case Studies

Several forward-thinking chemical manufacturers are already pioneering green nitrate production through technological innovation, strategic investment, and collaboration with academic and policy stakeholders. These early adopters are demonstrating that sustainability and industrial performance can go hand in hand.

Yara International, one of the world’s largest producers of fertilizers, is actively working to reduce its carbon footprint through the integration of renewable energy and low-emission technologies in nitric acid and nitrate production. The company has launched pilot projects focused on electrolytic ammonia production, which could feed into greener nitrate synthesis processes and significantly cut greenhouse gas emissions.

BASF, another industry leader, is investing in catalyst optimization and process electrification to improve energy efficiency and reduce nitrous oxide emissions from its nitrate and nitric acid production lines. Through partnerships with research institutions and tech providers, BASF is exploring zeolite catalyst technologies and carbon-neutral pathways as part of its broader climate roadmap.

In parallel, several pilot projects are scaling lab-scale innovations to industrial levels. Demonstration plants in Europe and Asia are testing electrochemical nitrate synthesis using wind or solar power, while other initiatives focus on capturing nitrogen-rich waste and converting it into high-purity nitrates suitable for agricultural or technical use.

These efforts are increasingly supported by government incentives, such as the European Union’s Green Deal and funding under programs like Horizon Europe, which promote decarbonization and circular economy initiatives in the chemical sector. Regulatory pressure, combined with market demand for sustainable products, is pushing more companies to adopt green chemistry practices in nitrate production, paving the way for a cleaner, more resilient chemical industry.

While global chemical leaders are advancing sustainable nitrate production, similar progress is taking shape within Serbia’s chemical sector, driven by innovation, environmental awareness and alignment with EU sustainability directives.

In Serbia, the growing alignment with EU environmental standards, particularly under the Green Agenda for the Western Balkans, is encouraging local industries to adopt circular economy models and invest in cleaner technologies. Government incentives, such as funding for energy efficiency upgrades and support for green transition projects through programs like IPARD and Innovation Fund grants, are further accelerating this shift.

Regulatory and Market Drivers for Sustainable Chemistry

The shift toward greener nitrate production is not only driven by innovation, but also by a growing network of regulatory frameworks and market expectations. In the European Union, policies like the EU Green Deal and the REACH regulation (Registration, Evaluation, Authorisation and Restriction of Chemicals) are setting ambitious targets for decarbonization, pollution control and chemical safety. These policies require manufacturers to minimize environmental and health risks, pushing the industry to adopt more sustainable, transparent practices across the supply chain.

In parallel, international guidelines such as EPA regulations in the United States are placing stricter limits on emissions and industrial waste, further encouraging a global transition toward cleaner chemistry.

Market forces are amplifying these regulatory demands. ESG (Environmental, Social and Governance) metrics are increasingly used by investors, stakeholders and procurement teams to evaluate a company’s long-term sustainability. Businesses that fail to demonstrate progress on these fronts may face reputational and financial risks.

Compliance is also becoming a competitive advantage. Certifications such as ISO 14001 for environmental management and alignment with UN Sustainable Development Goals (SDGs) can enhance credibility and market access, especially in regulated sectors like food, pharmaceuticals and agriculture.

For companies like DECACHEM, operating within both the EU market and international supply chains, adherence to these standards is not just about compliance - it’s about leadership. By aligning operations with evolving regulations and ESG expectations, DECACHEM strengthens its role as a responsible and reliable partner in the global transition to sustainable industry practices.

Challenges and Future Outlook

Despite the promising advancements in green nitrate production, several barriers remain on the path to large-scale adoption. One of the primary challenges is cost - greener technologies, such as electrochemical synthesis and advanced catalysts, often require significant upfront investment and may not yet match the efficiency of conventional methods at industrial scale.

Infrastructure limitations also slow progress. Many existing nitrate production plants are built around fossil fuel-based processes, making retrofitting or replacement costly and logistically complex. Additionally, some emerging solutions, such as biological or electrochemical methods, are still in the early stages of commercialization, with limited long-term performance data available.

However, the outlook for the next decade is optimistic. As renewable energy becomes more affordable, and as governments and investors continue to push for low-emission technologies, the cost gap between traditional and green methods is expected to narrow. Advances in catalyst design, process intensification and modular production systems will further accelerate this transition.

By 2035, decentralized, low-emission nitrate production could become standard in both industrial and agricultural sectors, supported by smart policy, market incentives and growing demand for sustainable chemical solutions.

Frequently Asked Questions (FAQs)

Q1: What makes nitrate production harmful to the environment?

Traditional nitrate production is

energy-intensive and relies heavily on fossil fuels, particularly in the

Ostwald process for nitric acid. This process emits

nitrous oxide (N₂O), a potent greenhouse gas, and often results in

air and water pollution, industrial waste and safety concerns related to high-temperature operations.

Q2: How does green chemistry improve nitrate manufacturing?

Green chemistry introduces methods that

reduce emissions, energy use and toxic byproducts. This includes innovations like

advanced catalysts,

electrochemical synthesis using renewable electricity and

biological pathways. These approaches make production cleaner, safer, and more resource-efficient.

Q3: Are green nitrates as effective as traditional ones?

Yes. Green nitrates maintain the

same chemical properties and performance as conventionally produced ones. The difference lies in how they’re made, using more

sustainable, low-impact processes that reduce environmental harm.

Q4: How can industries transition to sustainable nitrate sourcing?

Transitioning involves

evaluating suppliers for sustainability credentials, investing in

greener technologies, and participating in

government-funded modernization programs. Adopting

certifications like ISO 14001 and collaborating with forward-looking partners can accelerate this shift.

Conclusion

Green chemistry offers a transformative path forward for nitrate production - one that balances industrial performance with environmental responsibility. By embracing cleaner technologies, minimizing emissions, and rethinking resource use, the chemical industry can reduce its impact while meeting global demand.

Continued innovation, collaboration and regulatory alignment are key to making sustainable nitrate solutions the new standard.

At

DECACHEM, we are committed to advancing this transition through

eco-efficient practices and forward-thinking partnerships. To learn more about our sustainable product range or explore collaboration opportunities,

contact us today and join the movement toward

greener chemical sourcing.