Thermal Stability in Fertilizers: Why It Matters for Storage and Transport

Fertilizers are essential to modern agriculture, but their safe use extends far beyond the field. Around the world, accidents related to fertilizer storage and transport, sometimes resulting in fires, explosions, or contamination, remind us that safety is a global concern. This is where the concept of thermal stability becomes critical.

In simple terms, thermal stability describes a fertilizer’s ability to withstand changes in temperature without breaking down, decomposing, or becoming hazardous. Some fertilizers are more stable than others, but under the wrong conditions, even common products can pose risks. Understanding how fertilizers respond to heat is not just a technical detail — it is a cornerstone of responsible production, handling and logistics.

For producers, distributors, and end-users alike, maintaining stability during storage and transport ensures product quality, protects workers, and minimizes environmental hazards. It also helps safeguard global supply chains that farmers and food systems depend on.

In this article, we will explore what thermal stability means in practice, why it matters for fertilizer safety, the risks posed by instability, and how proper storage and transport protocols can reduce these risks. By the end, you will see why managing thermal stability is vital for both agricultural productivity and global safety.

Understanding Thermal Stability in Fertilizers

What is Thermal Stability?

Thermal stability refers to a substance’s ability to resist decomposition, chemical reaction, or structural change when exposed to varying temperatures. In the world of chemistry, it is a key property that determines how compounds behave under heat stress, storage conditions, and transport. A thermally stable compound remains safe and effective, while an unstable one may degrade, release gases, or in extreme cases, become explosive.

When

applied to fertilizers, thermal stability takes on critical importance. Fertilizers are often stored in bulk, transported across long distances, and exposed to different climates. If a fertilizer lacks stability, heat exposure during storage or transit can reduce its effectiveness by breaking down nutrients - or worse, create safety hazards for workers, facilities, and the environment. Maintaining stability ensures that the product arrives intact, retains its nutrient value, and can be safely applied in the field.

Types of Fertilizers and Their Thermal Properties

Not all fertilizers respond to heat in the same way. Their chemical composition largely determines how they behave under thermal stress:

Nitrogen-based fertilizers

Ammonium nitrate: Known for its high reactivity, ammonium nitrate can decompose at elevated temperatures, releasing gases and posing explosion risks if mishandled. This makes it one of the most closely regulated fertilizers worldwide.

Urea: More stable than ammonium nitrate, urea gradually breaks down into ammonia when heated. While less hazardous, improper storage in hot, humid environments can lead to nutrient loss and caking.

Phosphate fertilizers

Phosphates, such as monoammonium phosphate (MAP) and diammonium phosphate (DAP), generally display strong thermal stability. However, under excessive heat or moisture, they may lose some nutrient availability or form solid masses that complicate handling.

Potash fertilizers

Potassium chloride and potassium sulfate are among the most stable fertilizers under thermal stress. Their crystalline nature resists decomposition, though high humidity combined with heat may cause caking and handling issues.

Blended and specialty fertilizers

Fertilizer blends and specialty products can vary widely in stability, depending on their mix of nutrients and additives. While some formulations are engineered with coatings or stabilizers to resist heat and moisture, others may inherit the weaknesses of their most sensitive components.

Understanding these differences is essential for producers, distributors, and end-users alike.

Why Thermal Stability Matters

Risk of Decomposition and Combustion

When fertilizers lack sufficient thermal stability, exposure to heat can trigger chemical decomposition. This process not only reduces the nutrient value of the product but can also make it hazardous. For example, ammonium nitrate is particularly sensitive - under high temperatures or in confined storage, it can release oxygen and gases that accelerate combustion. If ignition occurs, the reaction may escalate into a large-scale explosion.

History provides sobering reminders of these risks. Incidents such as the

1947 Texas City disaster in the United States and more recent ammonium nitrate explosions in Beirut (2020) and Tianjin, China (2015) highlight the catastrophic potential of unstable fertilizers. These events caused widespread destruction, fatalities and long-term environmental impacts, underscoring why strict monitoring of fertilizer stability is non-negotiable.

Even less reactive fertilizers, such as urea or phosphate-based products, can lose their efficiency when exposed to excessive heat. While they may not explode, their decomposition diminishes agricultural value and can still present handling challenges.

Safety Concerns for Workers and Communities

Beyond product degradation, unstable fertilizers pose serious safety risks to people. When fertilizers decompose under heat, they may release toxic gases such as ammonia or nitrogen oxides. In poorly ventilated spaces, these emissions can harm workers’ health, causing respiratory problems, eye irritation, or more severe consequences with prolonged exposure.

The risk does not end at the warehouse gate. Fires or explosions involving fertilizers can endanger entire communities, spreading toxic smoke, contaminating water sources, and requiring large-scale emergency responses. Communities near storage or transport hubs are particularly vulnerable if safety protocols are not strictly followed.

Ensuring thermal stability is not just about protecting product quality, it’s about safeguarding people and the environment. By prioritizing proper storage, handling and logistics, the risks of decomposition, combustion, and toxic releases can be significantly reduced, ensuring fertilizers continue to serve their purpose: supporting agriculture safely and sustainably.

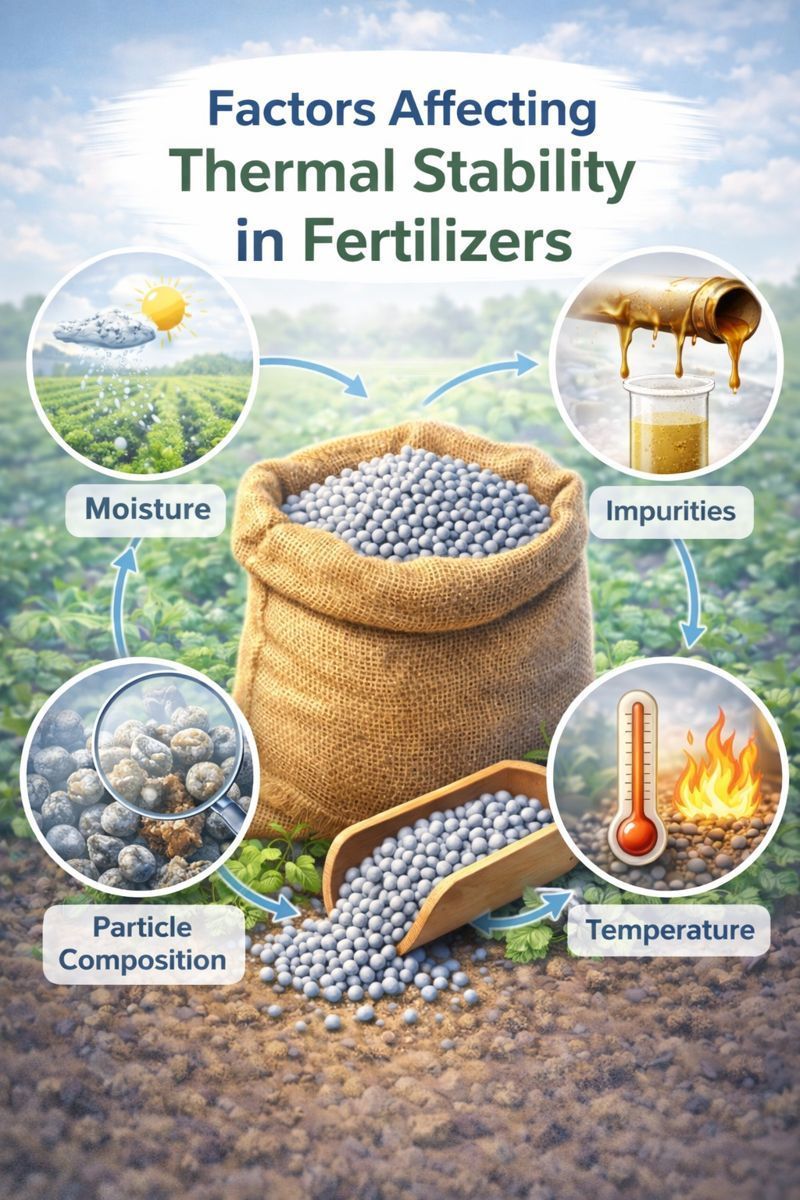

Factors Affecting Thermal Stability in Fertilizers

Chemical Composition

The primary factor influencing thermal stability is the chemical makeup of the fertilizer itself. Some compounds, such as ammonium nitrate, are inherently unstable when exposed to heat, while others, like potash fertilizers, remain stable under most conditions. Additives and coatings can be introduced to enhance stability, but impurities may have the opposite effect. For example, trace amounts of combustible materials or residual by-products can accelerate decomposition when exposed to elevated temperatures. Similarly, blended or specialty fertilizers combine multiple nutrients, and their stability depends on the compatibility of each component. A poorly formulated blend may inherit the weaknesses of its least stable ingredient.

Temperature and Humidity Conditions

Fertilizers are highly sensitive to environmental conditions, particularly temperature and humidity. Seasonal variations play a significant role - fertilizers stored in regions with hot summers or fluctuating temperatures face a greater risk of degradation. Excessive heat can drive chemical reactions, while high humidity promotes caking, lumping, or even partial dissolution of hygroscopic products like urea.

Climatic factors at storage sites also matter. Facilities in tropical or coastal regions must contend with both heat and persistent moisture, whereas fertilizers stored in temperate climates may experience risks primarily during summer peaks. Understanding and adapting to these local environmental challenges is critical to maintaining stability throughout the supply chain.

Packaging and Storage Conditions

The way fertilizers are packaged and stored is equally important. Bulk storage in large silos or warehouses can amplify risks if ventilation is poor or heat builds up within the mass of material. Localized heating points may trigger decomposition before problems become visible. By contrast, bagged fertilizers offer better airflow but may still absorb moisture if the packaging is not sealed properly.

Proper storage infrastructure is essential: warehouses should have adequate ventilation, moisture control systems, and clear separation between different fertilizer types. Controlling airflow and preventing condensation helps minimize both heat buildup and humidity exposure. Regular inspections and adherence to best practices ensure that fertilizers remain safe, effective, and stable.

Implications for Storage

Safe Storage Guidelines

Proper storage is the first line of defense in preserving fertilizer stability and preventing accidents. Temperature monitoring systems play a crucial role in this process, allowing operators to detect early signs of heat buildup or decomposition. Sensors and alarms provide real-time feedback, ensuring quick intervention before problems escalate.

Warehouse design is equally important. Storage facilities should be well-ventilated to prevent heat accumulation, with controlled humidity to reduce the risk of caking or premature reactions. Fertilizers should be kept away from direct sunlight, heat sources, and combustible materials. Segregation of incompatible products, such as separating ammonium nitrate from organic or flammable substances, is a critical best practice. Clear labeling, organized stacking, and accessible fire-fighting equipment further enhance warehouse safety.

Regulatory Standards for Storage

To reinforce safe handling, international and local regulatory bodies have established clear requirements for fertilizer storage. The Food and Agriculture Organization (FAO) provides detailed guidelines for the safe storage and transport of agricultural inputs, while organizations like OSHA (Occupational Safety and Health Administration) set workplace safety standards that apply to chemical storage facilities.

Local regulations may add further layers of oversight, especially in countries with histories of fertilizer-related incidents. Compliance with these rules is not only a legal obligation but also a critical safeguard for workers, communities, and the environment.

Beyond compliance, industry leaders follow best practices that go beyond minimum standards - regular staff training, emergency preparedness drills, and investment in modern monitoring technologies.

Advances in Fertilizer Thermal Stability Research

Innovations in Fertilizer Formulation

Recent research has focused on improving fertilizer formulations to enhance thermal stability and reduce risks during storage and transport. Stabilizers and coatings are among the most effective solutions. By adding chemical stabilizers, fertilizers like ammonium nitrate can resist premature decomposition, while polymer or sulfur coatings help regulate nutrient release and protect against temperature and humidity fluctuations. These innovations not only improve safety but also enhance field performance by reducing nutrient losses.

Another promising area is smart packaging solutions. Advanced materials with moisture barriers, heat-resistant linings, or oxygen absorbers are being developed to maintain stability under diverse climate conditions. Some packaging systems now incorporate sensors or indicators that signal if the fertilizer has been exposed to unsafe conditions, providing an additional layer of quality assurance.

Role of Technology and Monitoring Systems

Technology is also transforming how fertilizers are monitored throughout the supply chain. IoT-enabled temperature sensors can be embedded in warehouses, containers or even individual shipments to deliver real-time data on environmental conditions. This allows companies to detect and respond to risks before they escalate.

In parallel, predictive analytics powered by AI and big data is helping optimize logistics. By analyzing historical climate patterns, storage conditions, and transport routes, predictive models can anticipate risks and recommend preventive measures.

Case Studies of Fertilizer Storage and Transport Accidents

The dangers of poor fertilizer storage and transport practices are tragically illustrated by past accidents. Two of the most well-known incidents involve ammonium nitrate, a fertilizer with high agricultural value but significant safety risks if mishandled.

The Beirut explosion in 2020 is a recent reminder of the consequences of neglect. More than 2,700 tons of ammonium nitrate had been improperly stored in a port warehouse for years without adequate safety measures. When a fire ignited the stockpile, the resulting explosion devastated the city, killing over 200 people, injuring thousands, and causing widespread structural damage.

Similarly, the Texas City disaster of 1947 occurred when a cargo ship loaded with ammonium nitrate caught fire. The heat triggered a massive detonation, killing nearly 600 people and injuring thousands more. The blast remains one of the deadliest industrial accidents in U.S. history.

These incidents underscore the lessons learned for the fertilizer industry: thermal stability must be carefully monitored, storage conditions must meet strict safety standards, and transport requires proper labeling, segregation and training.

Practical Recommendations for Industry Stakeholders

For Manufacturers

Producers should prioritize thermal stability during fertilizer formulation. Using stabilizers, coatings, and quality control measures ensures products remain safe and effective. Regular testing for decomposition thresholds and adherence to international standards further reduces risks during storage and transport.

For Distributors and Transporters

Safe handling during logistics is critical. Vehicles and containers should meet regulatory standards, with proper ventilation and temperature monitoring. Staff must be trained in emergency procedures, chemical segregation, and safe loading practices to prevent accidents and maintain product quality.

For Farmers and End-Users

End-users play a vital role in maintaining fertilizer stability. Fertilizers should be stored in cool, dry conditions, away from incompatible chemicals or ignition sources. Following manufacturer guidelines for handling and application ensures safety, preserves nutrient value, and minimizes environmental impact.

FAQs on Fertilizer Thermal Stability

What makes some fertilizers more thermally unstable than others?

Thermal instability largely depends on chemical composition.

Nitrogen-based fertilizers, like ammonium nitrate, are more reactive and prone to decomposition under heat, whereas phosphate and potash fertilizers are generally more stable. Impurities, additives, and blends can also influence stability.

How can storage facilities minimize risks of thermal instability?

Facilities can reduce risks through temperature and humidity control, proper ventilation, regular inspections, and adherence to safe stacking practices. Segregating incompatible products and using protective packaging further enhances safety.

Are certain climates more dangerous for fertilizer storage?

Yes. Hot, humid climates accelerate chemical reactions and promote caking or decomposition. Seasonal temperature spikes in temperate regions can also pose risks if storage conditions are not adapted accordingly.

What role do government regulations play in fertilizer safety?

Regulations from organizations like the FAO, OSHA, and local authorities set standards for storage, transport, and handling. Compliance ensures consistent safety practices, reducing accidents and protecting workers and communities.

Can modern monitoring systems eliminate risks?

While IoT sensors, predictive analytics, and smart packaging significantly improve safety, they cannot eliminate risks. Vigilant management, training, and adherence to best practices remain essential to prevent incidents.

Conclusion

Thermal stability is a critical factor in ensuring fertilizers remain safe, effective, and reliable from production to application. Understanding how different fertilizers respond to heat and environmental conditions helps prevent decomposition, fires, and explosions, safeguarding workers, communities, and the environment. Maintaining stability not only preserves nutrient value but also enhances efficiency and supports sustainable agricultural practices.

By adopting modern monitoring technologies, following regulatory guidelines, and implementing best practices in storage and transport, the fertilizer industry can minimize risks and maximize product performance.

All stakeholders - from manufacturers to farmers - are encouraged to embrace these practices, invest in technology, and stay informed. Prioritizing thermal stability is not just a matter of compliance; it is a commitment to safety, quality, and sustainability in agriculture.